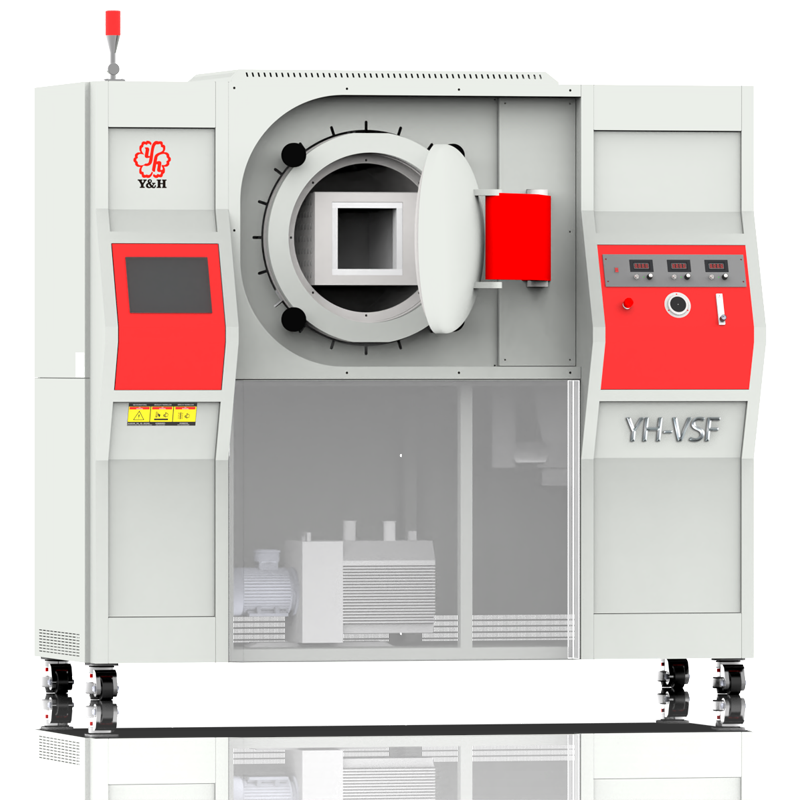

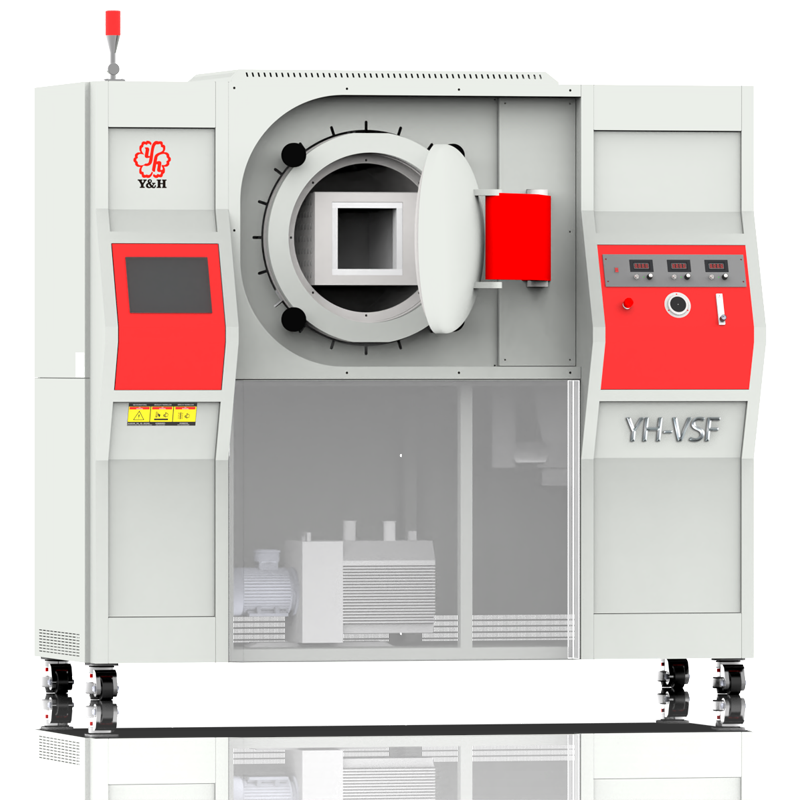

A vacuum furnace, also referred to as a vacuum sintering furnace, is typically an upgraded version of a sintering furnace. Compared to traditional sintering furnaces, it offers better sealing effectiveness. With enhanced sealing, it can be evacuated to a negative pressure state inside the chamber using a vacuum pump. Additionally, one or multiple gas routes can be introduced to create a purer atmosphere during the sintering process, thus mitigating the influence of air.

Vacuum sintering furnaces operate under reduced oxygen and gas conditions, effectively preventing oxidation, degassing, and chemical reactions of materials at high temperatures. They also offer more uniform temperature distribution and higher heating efficiency.

They are primarily used for sintering powder metallurgy materials, ceramics, and heat treatment of metal materials. Examples include sintering of precision ceramics, processing of high-temperature alloys, and production of hard alloys.

A vacuum sintering furnace creates a low-pressure vacuum environment, reducing oxygen and other gases inside the chamber to prevent oxidation and chemical reactions at high temperatures. Heating elements (typically resistance heaters) provide the necessary high temperatures to heat the samples to desired processing temperatures.

A vacuum sintering furnace is a device used for high-temperature processing of materials. It operates by heating samples in a vacuum environment to achieve sintering or other thermal treatment objectives, commonly used in powder metallurgy, ceramics, metals, and similar applications.