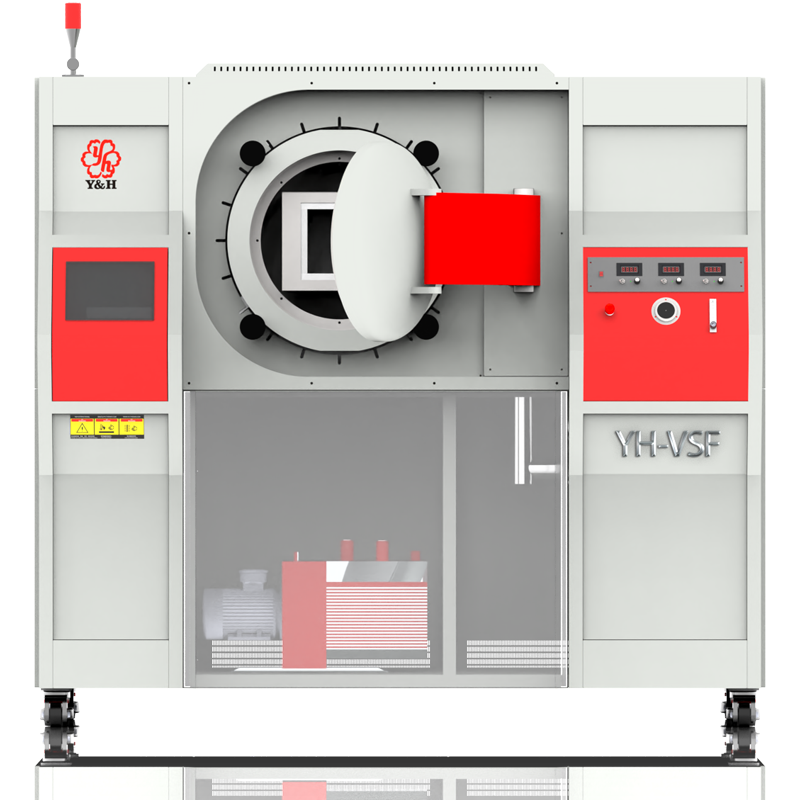

YH-VSF

Vacuum atmosphere sintering furnace is a heating device for high temperature treatment of materials, combining vacuum environment and atmosphere control functions. It is usually used in the sintering process of ceramics, powder metallurgy, metal manufacturing and other fields, and can be sintered under specific atmosphere conditions to achieve the purpose of densification, crystallization or alloying of materials. The temperature range is selected from 400-2000℃, and the vacuum degree is not greater than 0.001pa.

Standard Features:

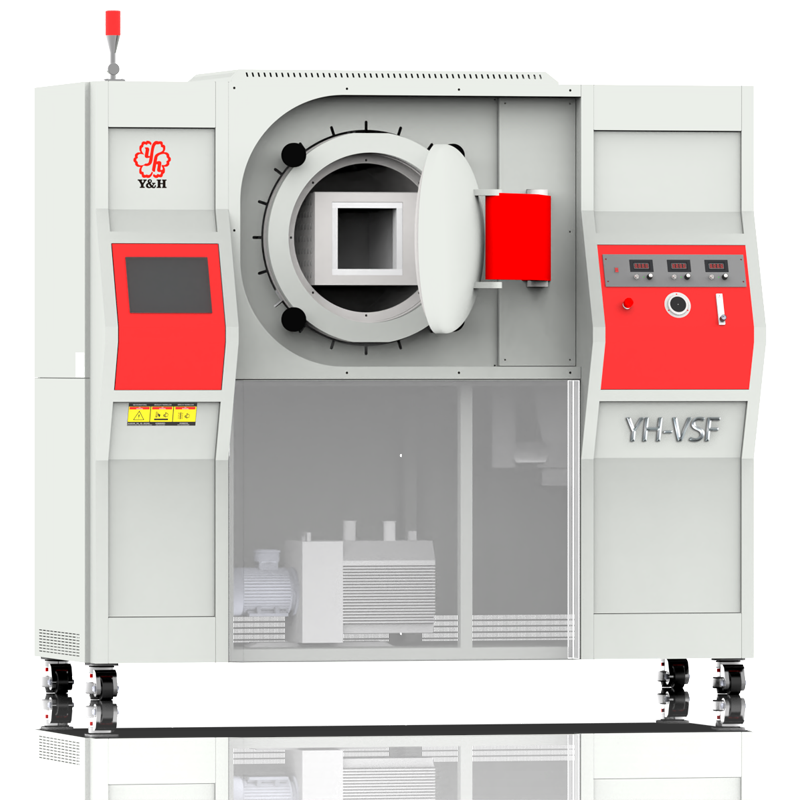

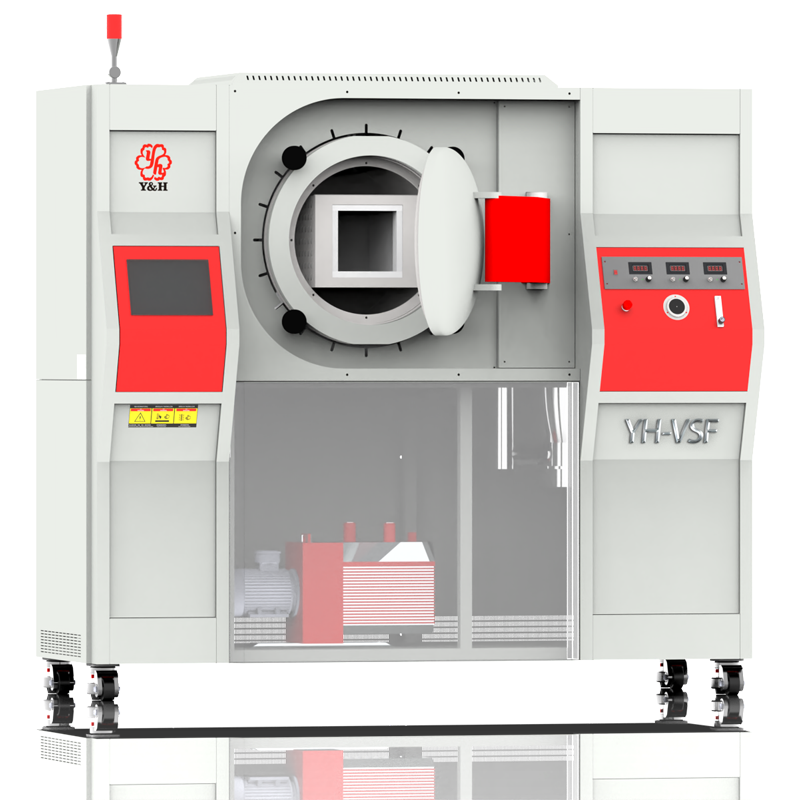

Vacuum structure: The shape of the vacuum atmosphere sintering furnace is similar to a round tank, and the internal space is used to place the material sample to be processed. Round tank type design can meet higher vacuum requirements.

Vacuum environment: Vacuum atmosphere sintering furnace can be heated in a vacuum environment. By removing oxygen and other gases in the furnace chamber, oxidation and degassing of the material can be prevented, and the purity and quality of the material can be improved.

Atmosphere control: In addition to the vacuum environment, the vacuum atmosphere box furnace can also control the atmosphere environment, such as nitrogen, argon and other inert gas environment. This helps control the chemical reaction, degassing and purity of the material.

High temperature heating: vacuum atmosphere box furnaces are usually able to provide high temperature heating, which can reach a temperature of up to 2000 ° C under air (tungsten heating). This makes them suitable for materials required for high temperature processing, such as metals, ceramics, glass, etc.

Precise control: Vacuum atmosphere box furnaces are usually equipped with high-precision temperature control systems, which can accurately control the temperature, pressure and atmosphere composition of the heating process to meet the needs of different material heating treatment.

Vacuum: Due to the characteristics of its structure, the vacuum atmosphere sintering furnace can carry higher pressure and vacuum, which can generally meet the positive and negative pressure of 0.001Pa. On the basis of the vacuum in the furnace, the atmosphere is introduced to make the sintering environment more pure.

Gas path and flow rate: Vacuum atmosphere box furnace is equipped with 2 standard air intake, including float flowmeter and pointer pressure gauge. Function and product expansion can be carried out on the basis of it.

Vacuum pump unit: The vacuum furnace is equipped with a mechanical rotary pump (which can meet the vacuum 0.1Mpa), and in order to meet the higher vacuum demand, Roots pump and diffusion pump and molecular pump units can be customized.

Optional Features:

Control mode customization: PID control by the traditional domestic instrument, can be customized imported instrument or PLC control. A variety of options to meet different customer habits.

Opening mode of the furnace door: the traditional opening mode is side opening, the opening direction and opening mode can be customized, manual, semi-automatic, automation are available.

Multi-sided heating: According to the size of the furnace, while ensuring the furnace temperature uniformity as much as possible, the Y&H provides additional multi-sided heating options to meet the requirements of higher furnace temperature uniformity.

Multi-point temperature control: According to the requirements of different use scenarios, customers can choose multi-sided heating to improve the heat radiation efficiency and the coverage of the furnace temperature.

Exhaust port and gas path: According to customer requirements, increase the exhaust port and gas path and flow meter to meet customer requirements for the process.

Touch screen control: YH can make touch screen control system according to the popular industrial touch screen collection on the market, reports, data, real-time observation and download.