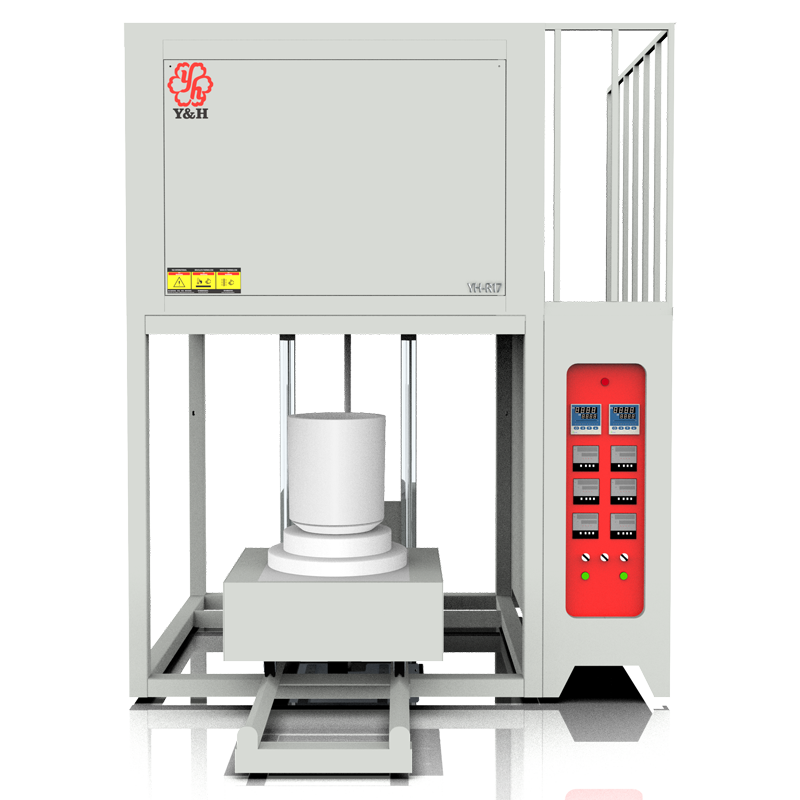

New Generation High-Temperature Vacuum Furnace Officially Launched

We are proud to introduce our latest innovation, the Advanced Vacuum Heat Treatment Furnace. This state-of-the-art furnace represents a significant leap forward in heat treatment technology, offering unparalleled performance and reliability.

[More...]

2024-07-10 15:48

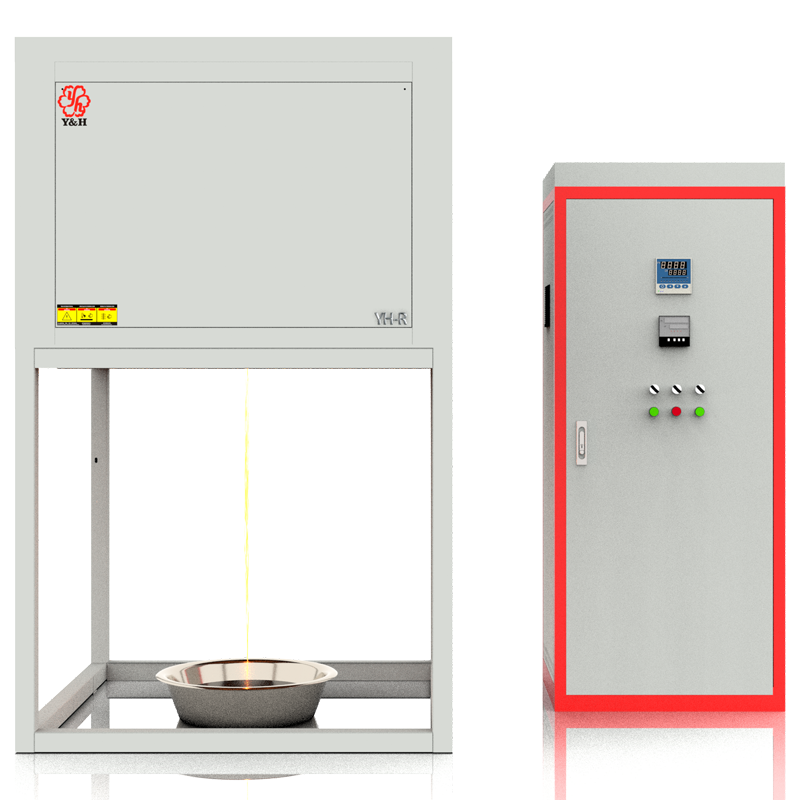

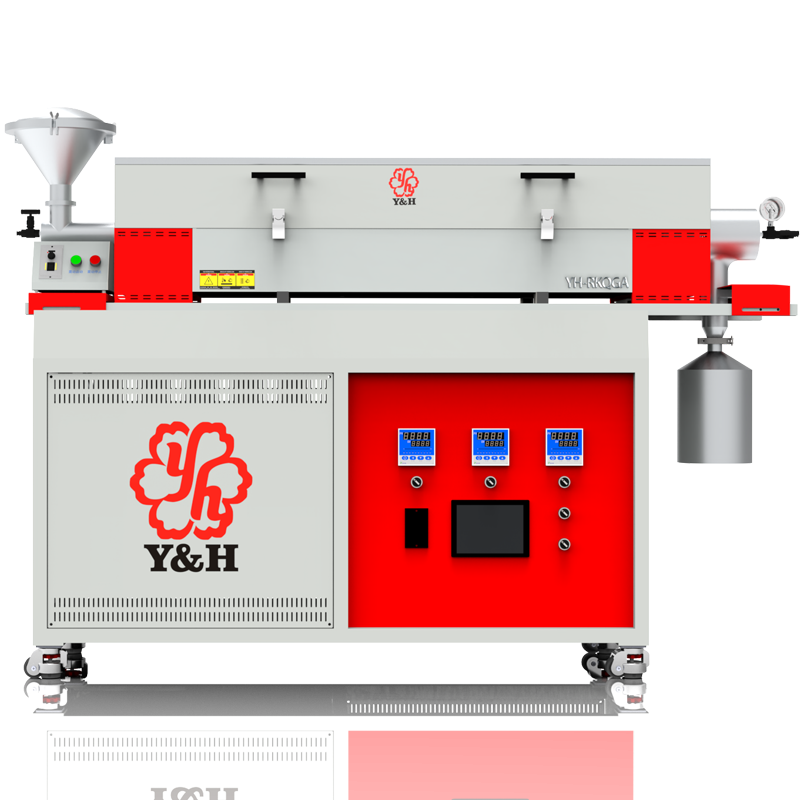

Y&H thermo successfully exports frit furnaces to Pakistan

Today, Y&H thermo (Luoyang Y&H International Trade Co., Ltd.) proudly announces that its latest production of molten metal furnaces has been successfully exported to Pakistan. This marks another breakthrough for the company in the international market, underscoring its strong technological prowess in the molten metal furnace industry.

[More...]

2024-03-28 16:20

Measurement and analysis of furnace temperature uniformity in high temperature furnace

Generally speaking, according to the requirements of the process and relevant technical documents, the maximum and minimum values of the temperature in the effective working area of the box furnace, the maximum deviation of the furnace temperature, the maximum and minimum values of the deviation from the set value of the volume can be obtained from the measurement results of the temperature uniformity of the high temperature furnace. However, the readings of the highest temperature value and the lowest temperature value in each measurement point should be selected during the entire measurement duration, and not read in the same measurement cycle. This allows you to see the time distribution of the temperature.

[More...]

2024-07-10 16:47

Common troubleshooting and precautions for high-temperature frit furnaces

As critical equipment in modern industrial production, the high-temperature frit furnace plays a crucial role in ensuring production efficiency and product quality. However, due to various factors, such furnaces inevitably experience malfunctions during operation. This article aims to discuss common malfunctions of high-temperature molten metal furnaces, along with their troubleshooting methods. It emphasizes the precautions necessary during use to ensure the equipment operates smoothly and to extend its service life.

[More...]

2024-07-11 15:34

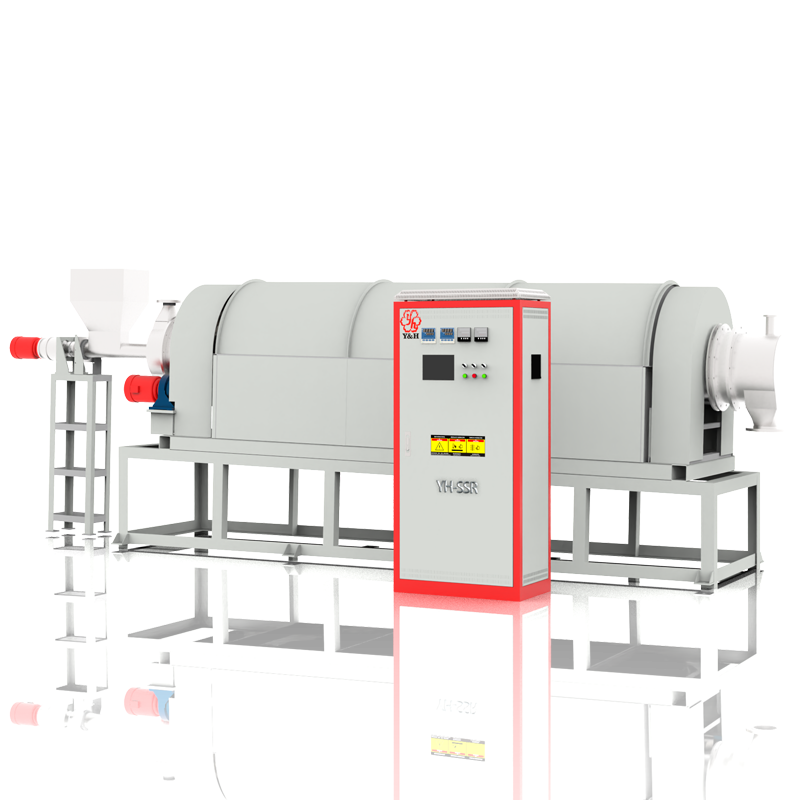

Application and rotation principle of rotary kiln

The rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a batch process. The basic components of a rotary kiln are the shell, the refractory linings, support tires (riding rings) and rollers, drive gear, and the heating elements. Y&H has designed different solutions according to the needs of different customers. Y&H is particularly good at sintering powder and particles containing water and organic matter in products with relatively rich production experience.

[More...]

2024-07-11 16:36

1700℃ molecular pump heating tube furnace (1.5 m heating zone)

Y&H a leading enterprise focusing on the research and development and manufacturing of resistance heating furnaces, has officially launched molecular pump tube furnace products, leading the innovation trend of the industry. As we all know, tubular furnaces at high temperatures are limited by the material of the furnace tube, and it is always impossible to achieve too large pipe diameter and heating area. According to the requirements and feedback of customers, combined with Y&H own advantages and cooperation with a group of excellent suppliers, the tube diameter of the 1700℃ corundum tube furnace is increased from the familiar 60mm to 80mm, and the tube length is increased from 1.5 meters to 2.1 meters. It can meet the requirements of 1.5 meters heating zone at high temperature.

[More...]

2024-07-11 17:14

Troubleshooting of Temperature Controller

Recently, we received feedback from a customer regarding their electric furnace, indicating that the temperature controller was unable to heat normally according to the set temperature and that the voltage and current meters were not displaying readings. Upon further inspection, we found that the temperature controller's PV was showing 1705, indicating an upper limit alarm. In response to this issue, our technical team quickly initiated an investigation to ensure the customer’s production was not affected.

[More...]

2024-10-24 14:01

Seeking Truth from Facts

Seeking truth from facts is a core value in Chinese culture and a fundamental principle for businesses to thrive in a competitive market. As a member of the high-temperature materials and equipment industry, Y&H deeply understands that seeking truth from facts is not merely a business philosophy but also a responsibility to the industry and customers.

[More...]

2024-12-17 10:03

Y&H 2024 New Year’s Message: Gratitude and Steady Progress

Time flies, and the final chapter of 2024 is about to close. This year has been one of effort and growth for Y&H, marked by teamwork and the trust of our customers. As we look back, we are filled with gratitude; as we look ahead, we are determined to keep moving forward with purpose.

[More...]

2024-12-31 20:34

- Previous

- Next