YH-ZQLB

A vacuum atmosphere box furnace is a type of high-temperature processing equipment that combines vacuum environment and atmosphere control functions. It is commonly used for sintering, annealing, heat treatment, and other processes, allowing for the heating treatment of materials under controlled atmospheric conditions. The temperature range typically ranges from 400 to 1800°C, with a vacuum level not exceeding 0.1 MPa.

Standard Features:

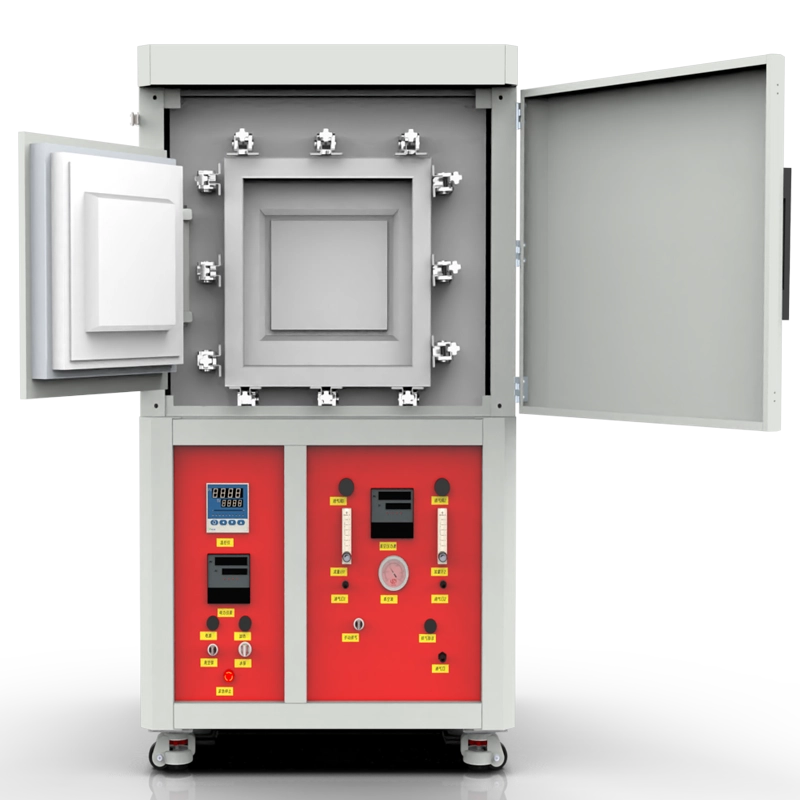

Box structure: The vacuum atmosphere box furnace has a box-like appearance, with internal space for placing the materials to be processed. The box structure design makes it suitable for processing a large quantity of samples.

Vacuum environment: The vacuum atmosphere box furnace can perform heating treatments in a vacuum environment. By eliminating oxygen and other gases from the furnace chamber, it prevents material oxidation, degassing, and other reactions, thus improving material purity and quality.

Atmosphere control: In addition to vacuum environment, the vacuum atmosphere box furnace can also control the atmosphere, such as nitrogen, argon, and other inert gas environments. This helps control material chemical reactions, degassing, and purity.

High-temperature heating: Vacuum atmosphere box furnaces typically provide high-temperature heating, reaching temperatures up to 1800°C under air. This makes them suitable for materials requiring high-temperature treatment, such as metals, ceramics, glass, etc.

Precise control: Vacuum atmosphere box furnaces are usually equipped with high-precision temperature control systems, allowing precise control of heating process temperature, pressure, and atmosphere composition to meet the requirements of different material heating treatments.

Vacuum level: Due to its structural characteristics, vacuum atmosphere box furnaces cannot withstand excessively high pressure and vacuum levels. They generally can meet positive and negative pressure of around 0.1 MPa. Initially, the furnace chamber is evacuated, then the atmosphere is introduced to make the sintering environment purer.

Gas path and flow: Vacuum atmosphere box furnaces come standard with two standard gas inlets, including a float flowmeter and a pressure gauge. Additional functionalities and product expansions can be added based on these.

Optional Features:

Customized control methods: Traditional domestic instrument PID control can be customized to imported instruments or PLC control. Multiple options are available to meet different customer usage habits.

Door opening methods: Traditional opening methods are side-opening, but door opening direction and methods can be customized, including manual, semi-automatic, and full automation.

Multi-side heating: Depending on the furnace size, additional multi-side heating options are provided by Y&H to ensure temperature uniformity while meeting higher requirements for furnace temperature uniformity.

Multi-point temperature control: Based on different usage scenarios, customers can choose multi-side heating to improve thermal radiation efficiency and furnace temperature coverage range.

Exhaust ports and gas paths: Additional exhaust ports, gas paths, flowmeters, etc., can be added according to customer requirements to meet process requirements.

Touchscreen control: Y&H can create touchscreen control systems based on popular industrial touchscreen models, providing reports, data, and real-time observation and download capabilities.

Standard specification

Specification Chamber Size(mm) ZQLB 200×150×150 300×200×200 300×300×300 500×300×200 500×300×300 600×400×400 800×500×500 Remark 1. The power data takes 1200 degrees Celsius as an example, and the selection of heating elements at higher temperatures has changed.

2. The vacuum atmosphere will affect the heating efficiency of the heating element, thus affecting the use temperature.

3. Power and voltage are reference values. The actual technical parameters prevail.

Vacuum atmosphere muffle furnace has a wide range of applications in material science, metal processing, ceramic preparation and other fields, which can provide a stable and controllable heating environment, which is helpful to realize the control of specific properties and structures of materials. It should be noted that if the use temperature in the air is 1700℃ high temperature furnace, under different atmosphere and vacuum degree, its use temperature will change. Please contact us for details.