High-temperature resistance heating elements refer to devices capable of operating stably and effectively generating heat under high-temperature conditions. These components are typically made from heat-resistant materials to meet demanding heating environments and high-temperature process requirements. Common types of high-temperature resistance heating elements include:

Resistance Wire: Resistance wire, commonly made of nickel-chromium alloys (such as typical heating elements), is a widely used high-temperature resistance heating element. It can operate stably at higher temperatures (approximately 1000°C to 1300°C) and is used in household appliances, industrial heating equipment, and laboratory heaters.

Silicon Carbide Rods: Suitable for higher temperature heating demands, silicon carbide rods can operate within the range of 1200°C to 1400°C. They exhibit excellent resistance to chemical corrosion and high temperatures, widely applied in industrial heating equipment and smelting processes.

Silicon Molybdenum Rods: Capable of operating at temperatures around 1700°C to 1800°C, silicon molybdenum rods are used in applications requiring higher temperature heating, such as glass melting furnaces and metal smelting equipment.

Molybdenum Heaters: Made from pure molybdenum, molybdenum heaters can operate stably at ultra-high temperatures under vacuum environments (approximately 1800°C and above). They are commonly used in vacuum furnaces, high-temperature heat treatment equipment, and semiconductor manufacturing processes.

Tungsten Heaters: Known for their extremely high melting point and excellent mechanical strength, tungsten heaters can operate at temperatures well above 2000°C(Under high vacuum environments). They are used in extreme high-temperature heating applications such as high-temperature melting and laboratory research.

These high-temperature resistance heating elements not only possess high-temperature resistance but also typically exhibit good corrosion resistance and long service life. They are suitable for various industrial and laboratory applications requiring precise control of high-temperature heating processes.

Different atmospheric conditions, such as oxidizing, reducing, or inert atmospheres, significantly affect the heating efficiency and stability of resistance heating elements. In oxidizing atmospheres like air, elements may oxidize or degrade at high temperatures, impacting long-term heating performance. In reducing atmospheres (e.g., hydrogen or hydrocarbon gases), chemical reduction can alter the material's resistance or induce reactions that affect heating capabilities. Conversely, inert atmospheres (e.g., nitrogen or argon) typically maintain stable conditions for the elements, avoiding chemical reactions or oxidation. Therefore, selecting and using resistance heating elements involves considering the atmospheric conditions of the operational environment to ensure stable and efficient heating performance.

Resistance heating elements can operate within a temperature range dependent on their specific materials and design, typically spanning from tens of degrees Celsius to several thousand degrees Celsius, with examples including nickel-chromium alloys reaching up to about 1200°C, silicon carbide exceeding 1500°C, and molybdenum disilicide up to 1850°C in oxidizing atmospheres, suitable for various industrial applications such as high-temperature heating and metallurgical processes.

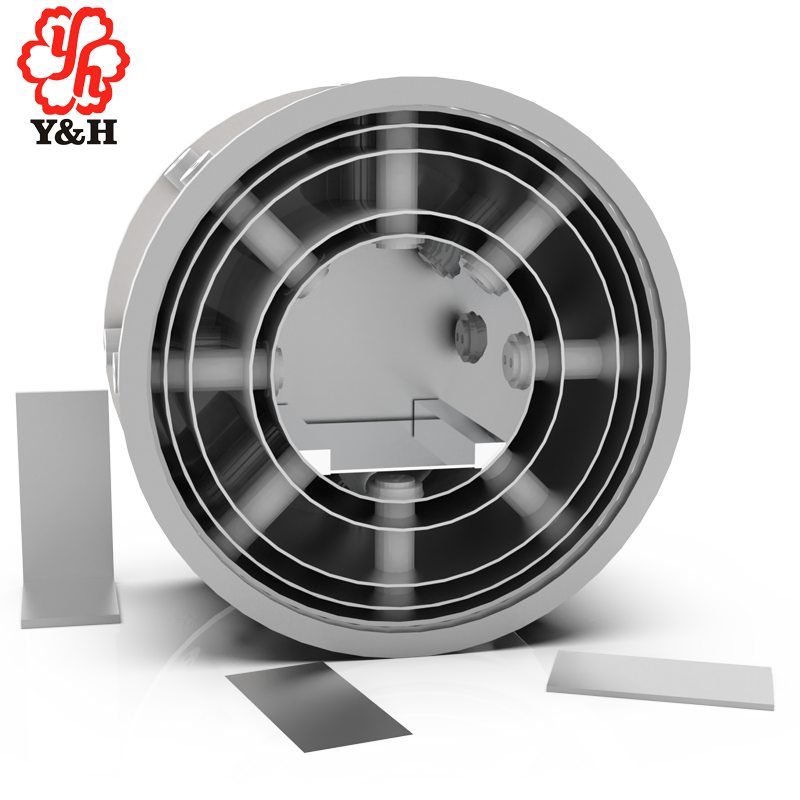

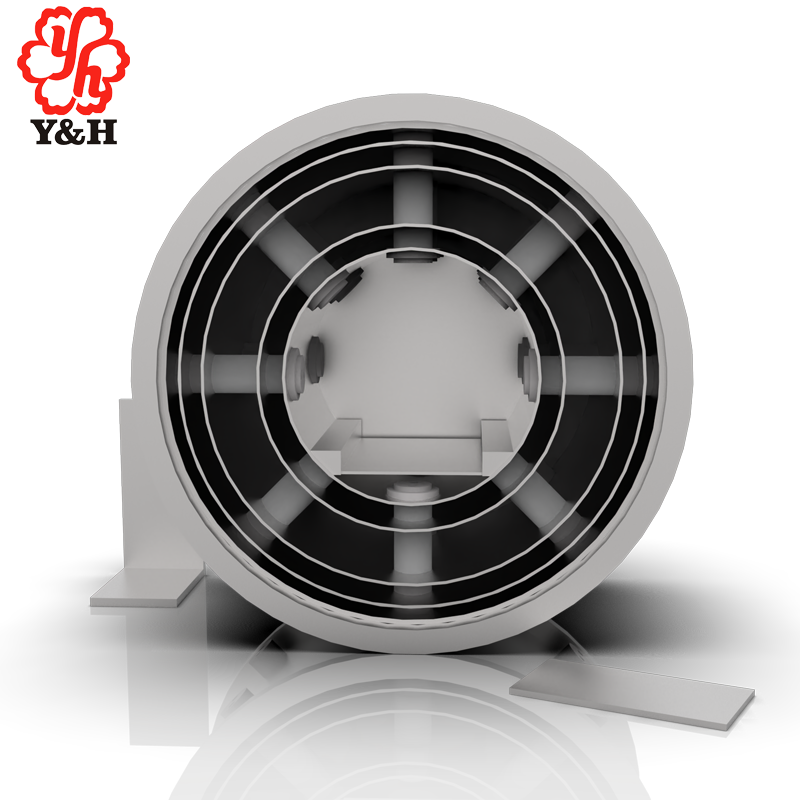

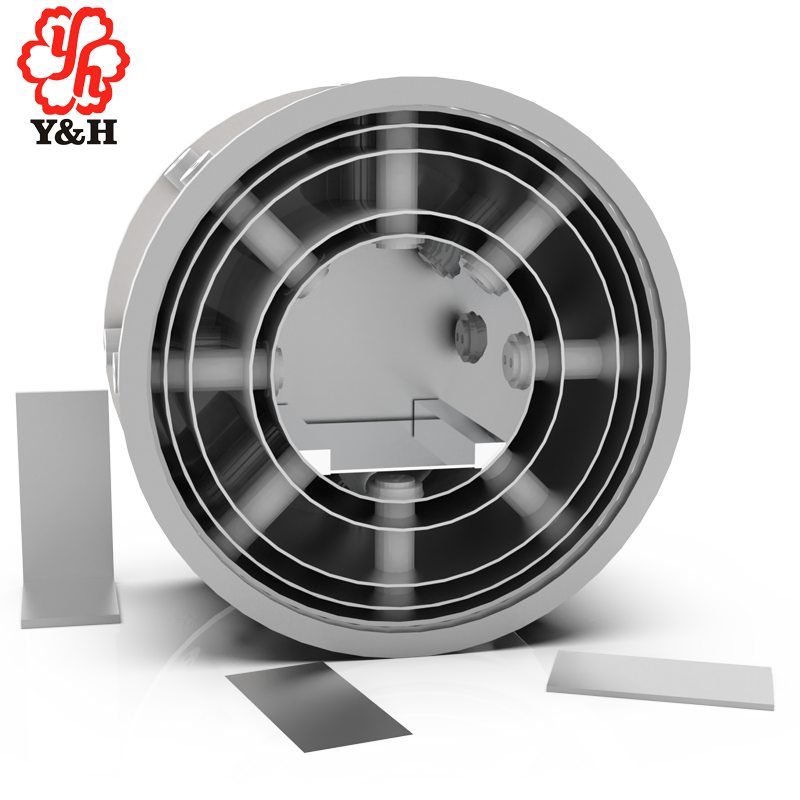

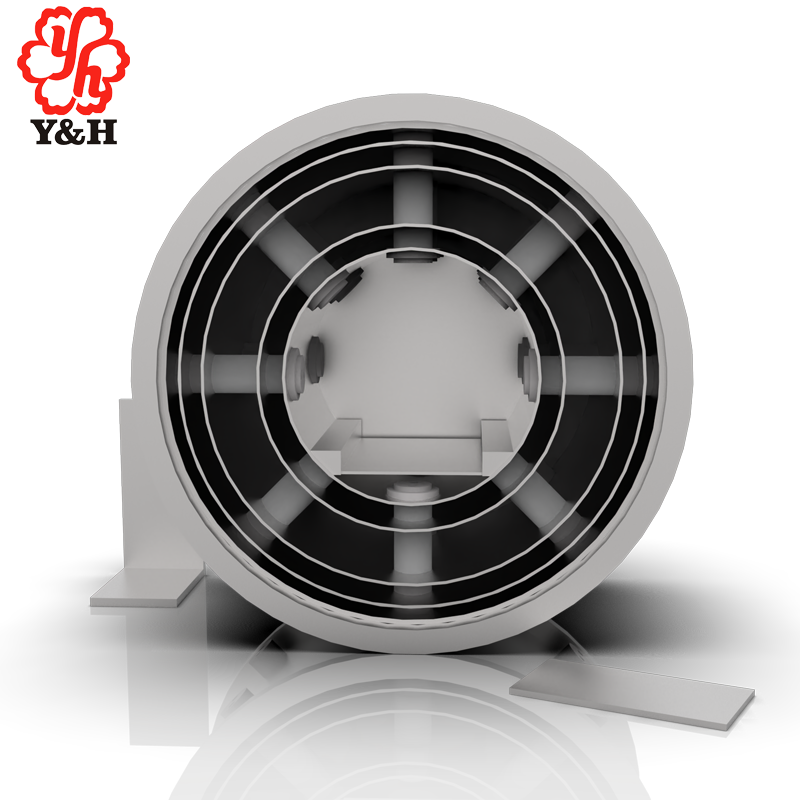

The heating elements of an electric furnace are crucial components that generate heat through resistive effects. The main types include resistance heating wires (such as nickel-chromium alloys), silicon carbide rods (Sic), molybdenum disilicide rods (Mosi2), and graphite elements. They are tailored for various industrial heat treatment needs, capable of operating stably in high-temperature environments and efficiently converting electrical energy into heat to meet the heating and temperature control requirements of electric furnaces.