Molybdenum Product

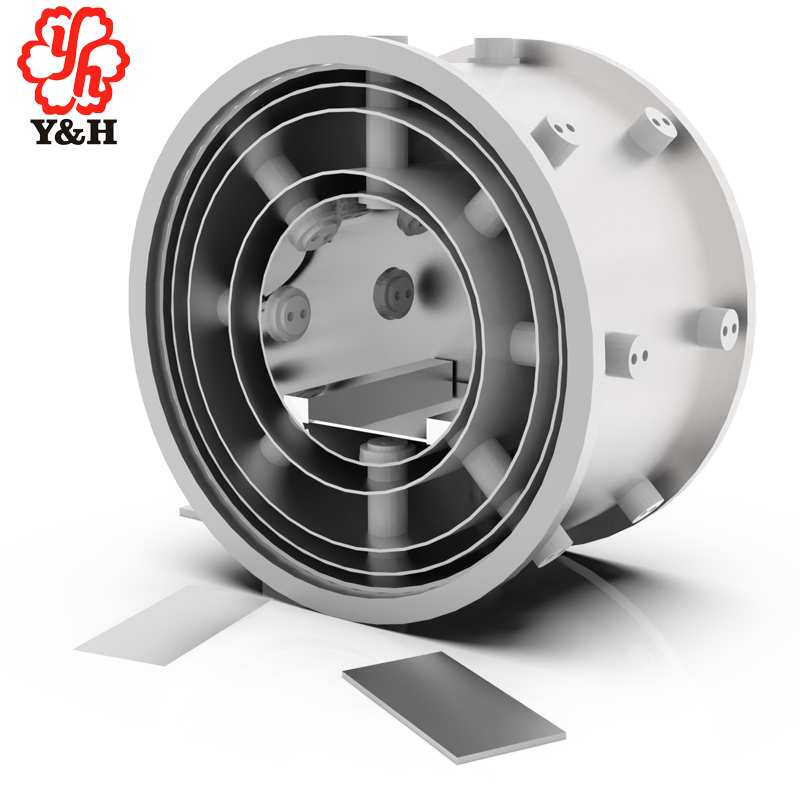

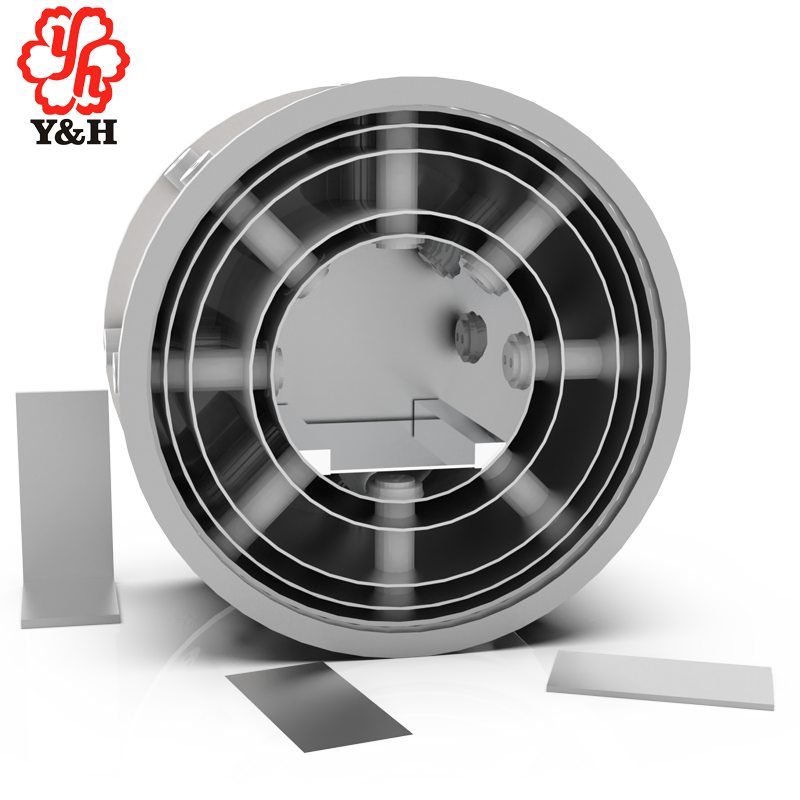

Molybdenum heating elements and reflector screens are specific components made from molybdenum, used for heating and reflecting functions in high-temperature applications. The primary reason for choosing molybdenum as a heating element and reflector screens is its ability to meet high-temperature requirements in various atmospheres. Additionally, molybdenum-made reflector screens and furnace chambers made from other metals can meet the high vacuum sealing requirements. These heating elements and reflector screens are commonly used in semiconductor processing equipment, vacuum heat treatment furnaces, vacuum melting furnaces, and similar devices.

Molybdenum possesses characteristics such as high strength, high hardness, low coefficient of thermal expansion, and excellent heat and corrosion resistance. Therefore, molybdenum sheets are commonly used in high-temperature furnaces as thermal shields, heating elements, sintering boats for high-temperature processes, molybdenum substrates, and support materials. Molybdenum sheets can be processed into molybdenum sputtering targets for PVD coating or thin film deposition, and molybdenum ion sources for ion implantation equipment, such as molybdenum side plates, molybdenum cathodes, and molybdenum arc chambers.

| Property | Description |

|---|---|

| Material | Molybdenum |

| Standard | ASTM B386 |

| Purity | Molybdenum ≥99.95% |

| Surface | Alkali washed, polished, sandblasted |

| Density | >10.15 g/cm³ |

| Melting Point | 2610 °C |

Molybdenum plates are produced through a process of pressing and sintering molybdenum ingots, followed by rolling. Typically, plates with thicknesses ranging from 2 to 30 millimeters are referred to as molybdenum plates, those with thicknesses of 0.2 to 2 millimeters are called molybdenum sheets, and those below 0.2 millimeters thick are known as molybdenum foils. Molybdenum plates of different thicknesses require different types of rolling mills for manufacturing. Thinner molybdenum sheets and foils exhibit good flexibility and can be produced through continuous rolling with tension, then supplied in rolls, known as molybdenum strips.

Molybdenum-processed products are extensively used in various applications including:

Sapphire crystal and vacuum furnace components such as molybdenum thermal insulation screens, heating elements, internal support frames, and boats.

Monocrystalline silicon industry components like flow tubes, molybdenum hooks, hangers, and feeders.

Vacuum coating industry for manufacturing molybdenum boats, cathodes, and molybdenum targets.

High-temperature resistant parts, such as components for ion sources in ion implantation equipment.