High Temperature Resistance Wire

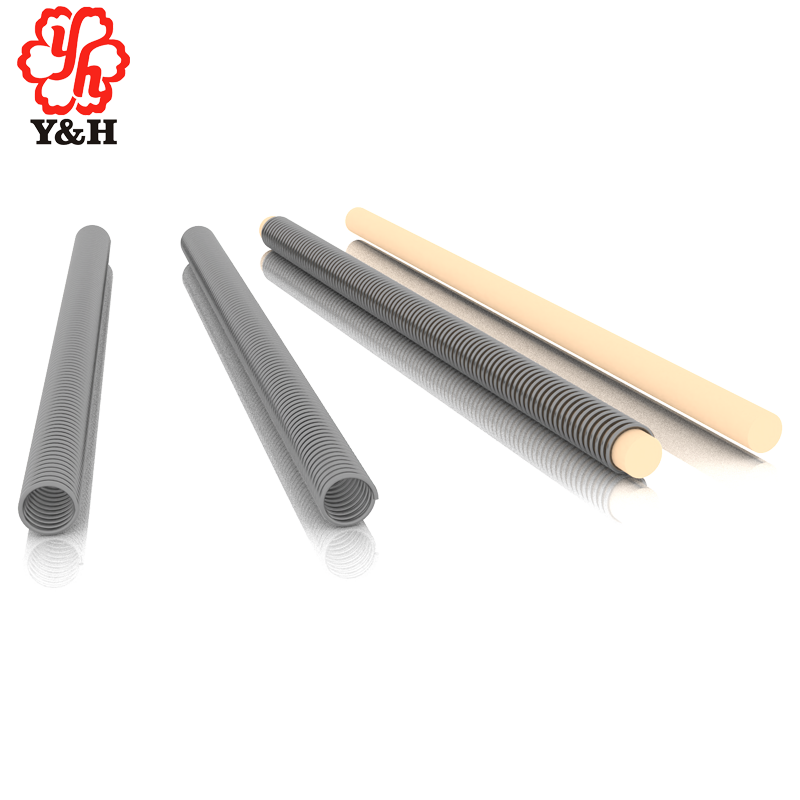

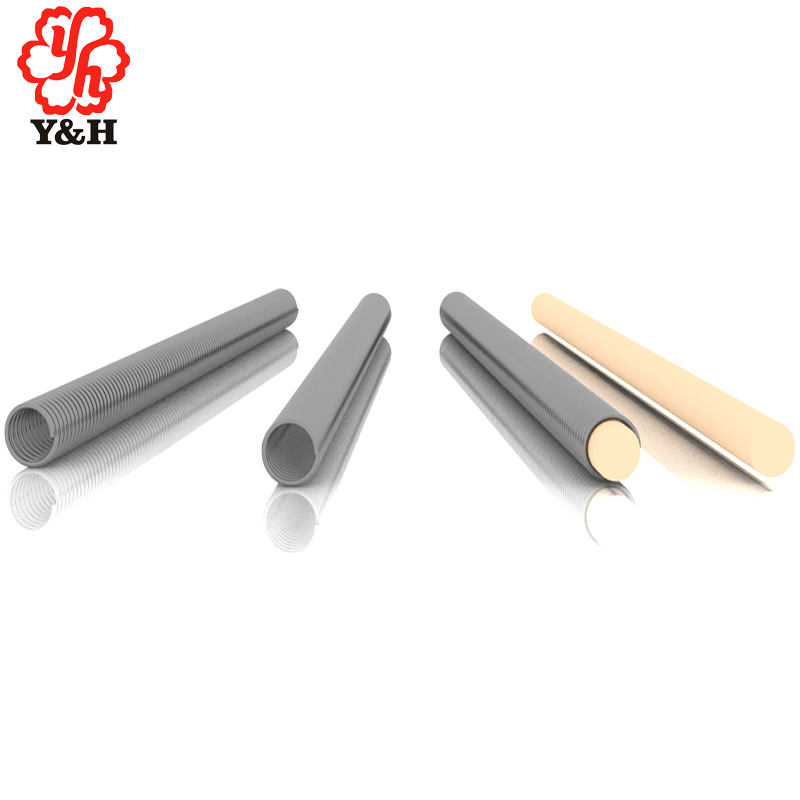

The resistance wire heater is a highly efficient and reliable heating device widely used in industrial heating and heat treatment applications. It utilizes high-quality metal alloy resistance wires such as Nichrome and FeCrAl as heating elements. By passing electric current through the resistance wire, it generates heat, ensuring stable operation and long-term durability in high-temperature environments.

This heater is versatile in design, and customizable into various shapes and sizes such as coils and spirals to meet diverse heating requirements. It finds extensive use in industrial equipment such as drying machines, ovens, heat guns, and heating pipelines, providing rapid heating response and stable temperature control to enhance production efficiency and product quality.

Y&H offers a range of quality specifications of resistance wires from renowned brands like Kanthal and Shougang HRE, ensuring customers receive the best solutions when selecting and applying resistance wire heaters.

Parameters for resistance wire:

Material/Type | Main Components | Maximum Operating Temperature | Characteristics and Applications |

|---|---|---|---|

Nichrome | Nickel (Ni), Chromium (Cr) | Approx. 1200°C | High resistivity, good oxidation resistance, commonly used in heating elements and resistors. |

FeCrAl | Iron (Fe), Chromium (Cr), Aluminum (Al) | Approx. 1400°C | High resistivity, excellent mechanical strength and heat resistance, used in industrial heating equipment. |

Ocr21Al6Nb | Chromium (Cr), Aluminum (Al), Niobium (Nb) | Approx. 1200°C | High temperature and good oxidation resistance, suitable for heat treatment furnaces and high-temperature heaters. |

Kanthal A1 | Chromium (Cr), Aluminum (Al) | Approx. 1400°C | High oxidation resistance, good tensile strength and modulus of elasticity, used in industrial heating equipment. |

Shougang HRE | Iron (Fe), Chromium (Cr), Aluminum (Al) | Approx. 1400°C | Excellent high temperature stability and oxidation resistance, ideal for demanding industrial heating applications. |