Tungsten products

Tungsten products are essential for high-density, strength, and temperature resistance applications. Common tungsten products include rods and wires used in heating elements for electronic devices and high-temperature furnaces, alloys that enhance hardness and wear resistance in aerospace, defense, and medical equipment, targets crucial for X-ray generation in medical imaging and semiconductor manufacturing, as well as tungsten-molybdenum components for thermal shielding and structural support in high-temperature furnaces and hot-working processes. Tungsten-palladium alloys also serve in catalytic and high-temperature corrosion-resistant applications. Overall, tungsten's superior physical and chemical properties make it indispensable across electronics, aerospace, medical, and industrial sectors.

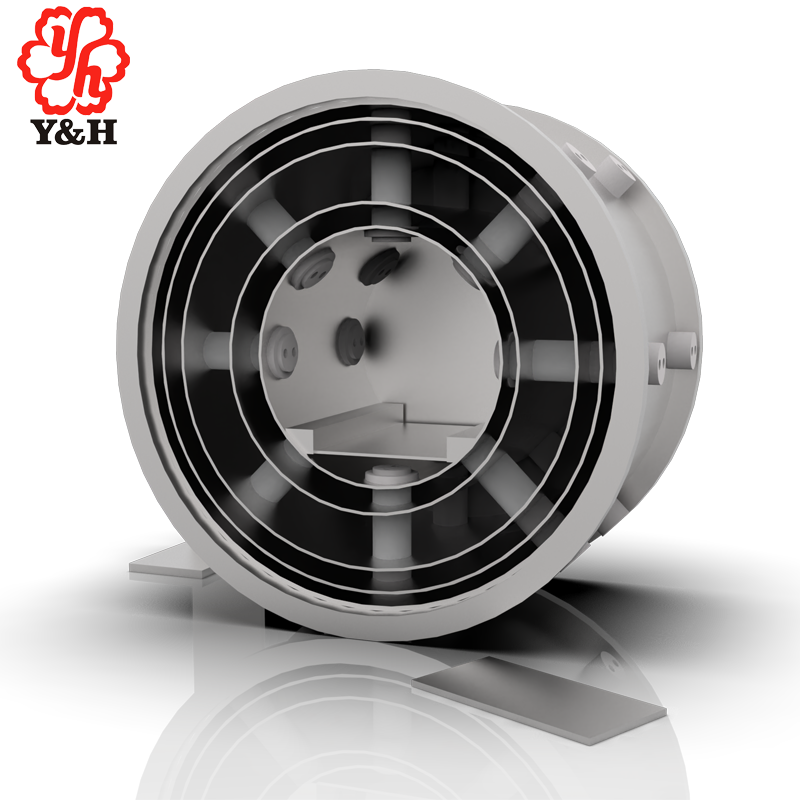

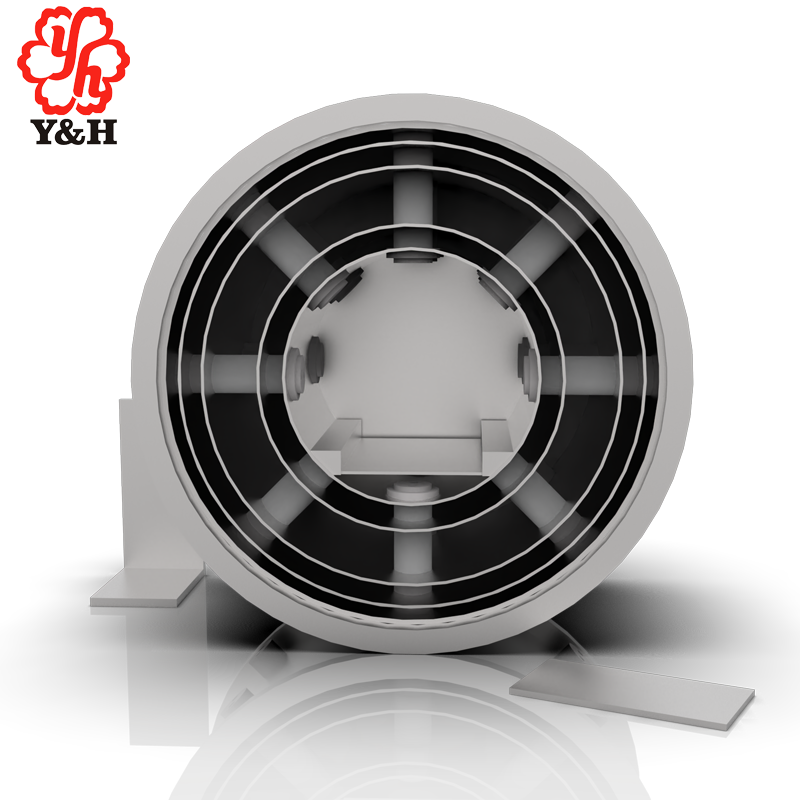

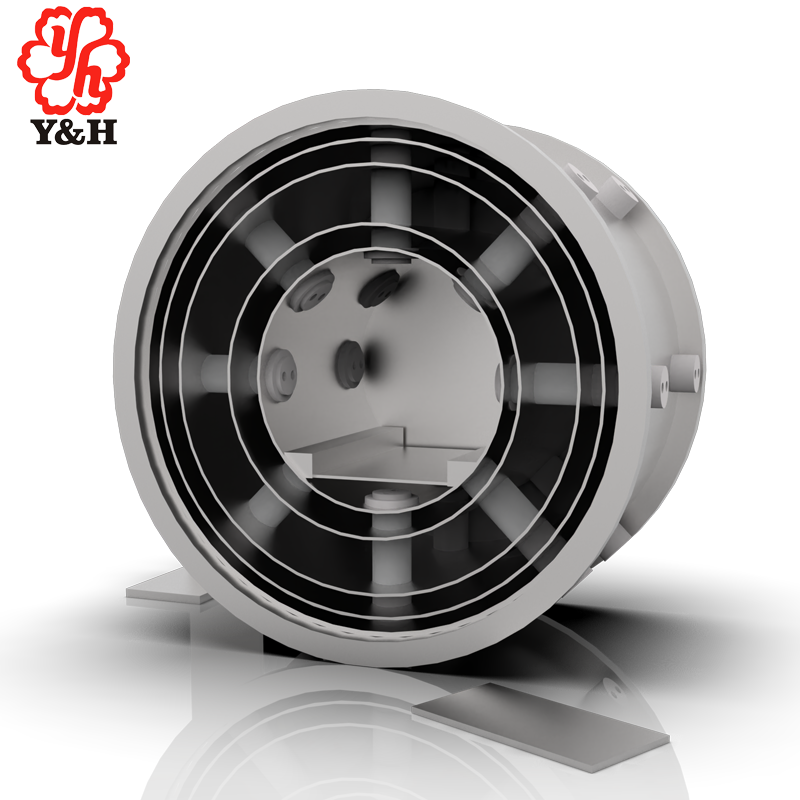

Tungsten heating elements are high-performance components typically used in thermal processing and materials processing equipment requiring extremely high temperatures. Tungsten, with its exceptionally high melting point (3422°C) and excellent mechanical stability, performs exceptionally well in high-temperature applications.

| Property | Description |

|---|---|

| Purity | 99.95% |

| Grade | TW-1, TW-2/TW-4 |

| Impurity Content | 0.05% |

| Hardness | 7.5 HB |

| Density | 19.35 g/cm³ |

| Melting Point | 3420℃ |

Tungsten-processed products are widely used in:

Sapphire crystal furnaces and vacuum furnaces: tungsten thermal insulation screens/thermal shields, furnace supports, loading boats, etc.

Monocrystalline silicon industry: tungsten thermal shields.

Vacuum coating industry: tungsten boats for evaporation coating, tungsten cathodes, tungsten planar targets.

Semiconductor and electronic industries: tungsten planar heating elements for MOCVD, LED chip substrates, high-temperature resistant parts for MOCVD, and components for ion sources in ion implantation equipment.

Medical device industry: manufacturing CT scanner collimator blades.