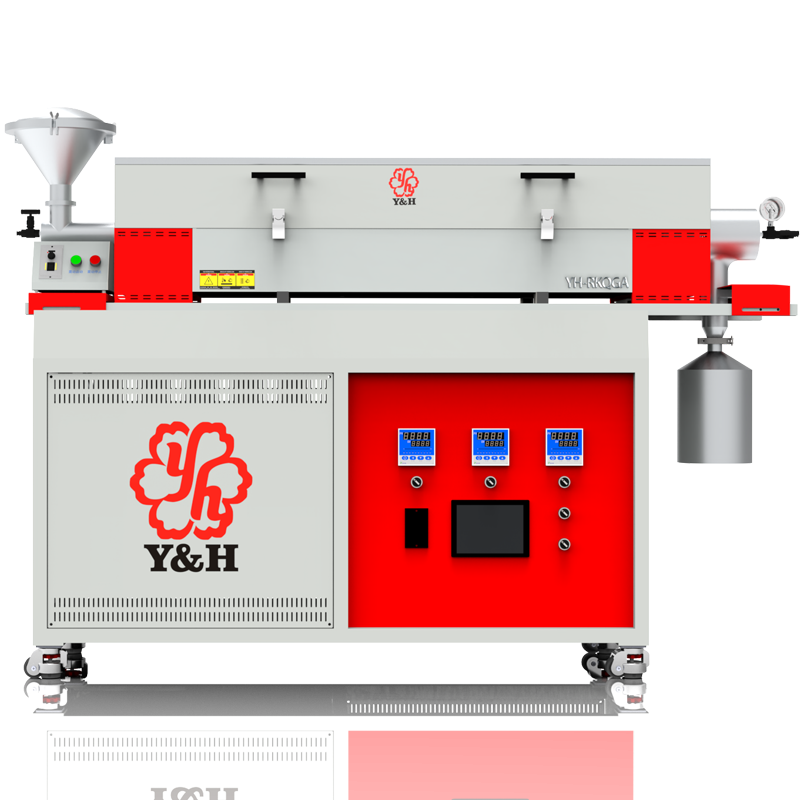

YH-RKQGA

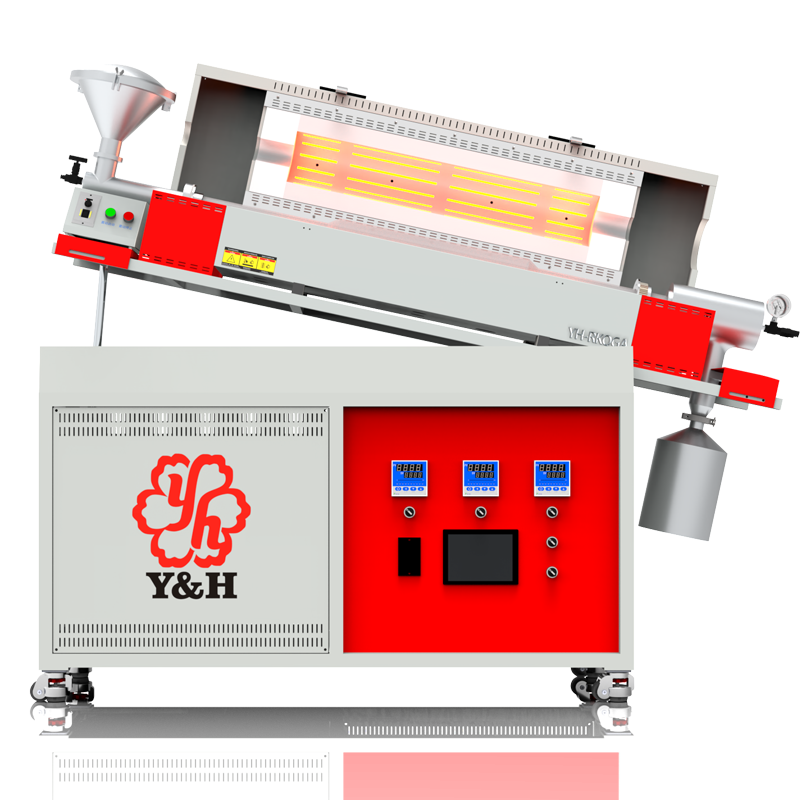

The YH-RKQGA Multi-Temperature Tilt-Rotary Tube Furnace Series uses the same process developed for the KQGA Split Tube Furnace Series with the addition of a tilt-rotary function, which allows for uninterrupted transport of the material into the inner tube of the electric furnace by means of a feeder and uniform heating of the material by means of electrical resistance heating for increased productivity.

The YH-RKQGA series consists of a split-tube furnace mounted horizontally on a base frame, equipped with a rotary system that rotates the working tube at speeds of up to 20 rpm. The furnace frame can be tilted electrically up to a maximum tilt angle of 7˚ to meet the requirements of the material being processed.

Accessory work tubes can easily be exchanged to meet the different physical or chemical requirements of a process.

Standard Features:

Tube structure: The heating chamber typically adopts a tube structure, usually made of high-temperature resistant materials such as stainless steel, quartz, silicon carbide, or high-purity ceramics. The tube structure helps provide uniform heating and can accommodate samples of different shapes and sizes.

Refractory materials: The furnace chamber is lined with ceramic fiber boards as refractory materials, and the outer layer is filled with ceramic fiber blankets or cotton, which not only insulates against high temperatures but also conserves energy.

Heating elements: Internal heating elements, usually resistance wires or silicon carbide rods and molybdenum disilicide rods, generate high temperatures to raise the temperature inside the heating chamber to the desired level.

Temperature control: The tube furnace is equipped with a temperature control system (temperature controller) to precisely control the temperature inside the heating chamber. This helps achieve precise control over the heating process of the samples.

Safety features: Laboratory tube furnaces typically include safety features such as overheat protection and safety door locks to ensure the safety of the experimental process.

Gas and vacuum: Tube furnaces typically include one gas inlet and a 4L mechanical vacuum pump under standard conditions. Additional customization can be made for larger vacuum requirements or gas inlet numbers as needed.

Vacuum pump selection: Depending on the specific vacuum requirements of the tube furnace, additional customization options such as diffusion pumps or molecular pump units can be provided, with a maximum vacuum degree of up to 0.0001 Pa.

Optional Features:

Furnace chamber opening: Standard tube furnace chambers cannot be opened, but customizable openable chambers facilitate observation of the material entering the tube and offer other advantages. However, it's important to note that tube furnaces heated by molybdenum disilicide rods cannot be opened.

Gas inlet number: The number of gas inlets can be customized according to customer requirements, ranging from one to multiple inlets. Standard options include float flow meters, and digital flow meters can also be customized.

Gas atmosphere: Tube furnaces can introduce various atmospheres, from standard inert gases to custom gases such as hydrogen or chlorine.

Touchscreen control: In addition to standard temperature controller control, touchscreen control can be customized according to different customer needs, offering data visualization and convenient operation, with the ability to download and archive data at any time, eliminating the cumbersome traditional paper recorders.

Feeding methods: Tube furnaces can be customized with tilting/vibrating feeding methods for continuous processing of products under non-atmospheric and vacuum sintering conditions.

Standard Specifications:

The standard specifications of a tube furnace depend on the diameter of the furnace tube and the length of the heating zone. Generally, they can be divided into the following two cases:

When operating at temperatures below 1200°C for extended periods, you can choose either stainless steel or quartz tubes as the furnace tube material. Tube diameters ranging from 30mm to 500mm are customizable, The overall heating zone can be extended through a splicing method, theoretically achieving lengths of several meters or even tens of meters.With each 500mm extension of the heating zone forming an independent temperature zone.

When operating at temperatures above 1200 degrees Celsius, the furnace tube should be made of either silicon carbide or high-purity alumina. Due to limitations in tube size, the maximum diameter achievable is 80mm, with a heating zone length of 1.5 meters (total tube length 2.1 meters).

If customers have suggestions for better materials, they are welcome to contact us for further discussion.