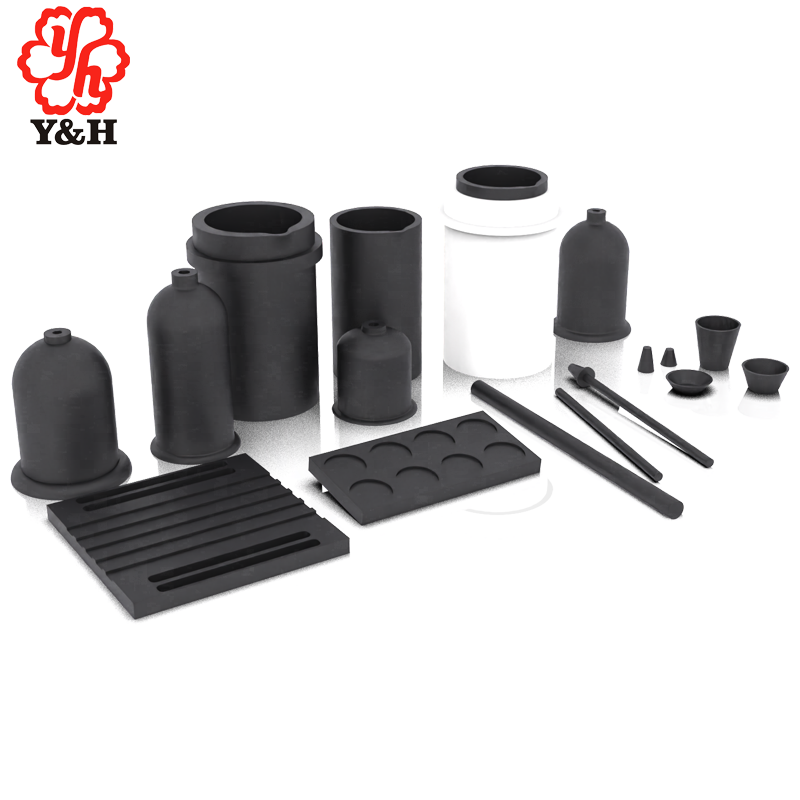

Graphite Crucible

Graphite crucibles are primarily made from natural flake graphite, processed with plastic refractory clay or carbonaceous binder. They feature high-temperature resistance, strong thermal conductivity, excellent corrosion resistance, and a long lifespan. They exhibit low thermal expansion coefficients and moderate resistance to rapid heating and cooling during high-temperature operations. They demonstrate strong resistance to acidic and alkaline solutions, exceptional chemical stability, and do not undergo any chemical reactions during the smelting process. The smooth interior surface of graphite crucibles prevents molten metal from leaking or adhering, ensuring good flow and casting properties suitable for various mold casting applications. Due to these superior characteristics, graphite crucibles are widely used in the smelting of alloy tool steels and non-ferrous metals and their alloys.

Our company uses graphite crucibles primarily made from fine-grain graphite and high-purity graphite as the main materials, used for melting platinum, gold, and other alloys. The physical and chemical specifications are as follows: Carbon content greater than or equal to 99.5%, ash content less than or equal to 0.3%. The specifications and models can be customized to different shapes and sizes according to customer requirements.

Characteristics of high-quality graphite crucibles:

High Density: High density provides excellent thermal conductivity, surpassing other imported crucibles in heat transfer efficiency.

Special Glaze and Dense Molded Material: The crucible's exterior is coated with a special glaze and dense molding material, significantly enhancing its corrosion resistance and extending its lifespan.

Natural Graphite Composition: The crucible is made entirely from natural graphite, ensuring exceptional thermal conductivity. After heating, it should not be placed immediately on a cold metal surface to prevent rapid cooling and potential cracking.

| Parameter | Value |

|---|---|

| Density | 1.87 g/cm³ |

| Ash Content | 0.05% |

| Flexural Strength | 50 MPa |

| Compressive Strength | 95 MPa |

| Particle Size | 0.01 mm |

| Electrical Resistivity | 10.5 μΩ·m |

| Refractoriness | 2100°C |

| Shore Hardness | 60 HSD |

| Thermal Expansion Coefficient (Room temperature - 600°C) | 4.5 x 10-6/°C |

Parameters are for reference only; actual values may vary. Please refer to the specific product for precise details.