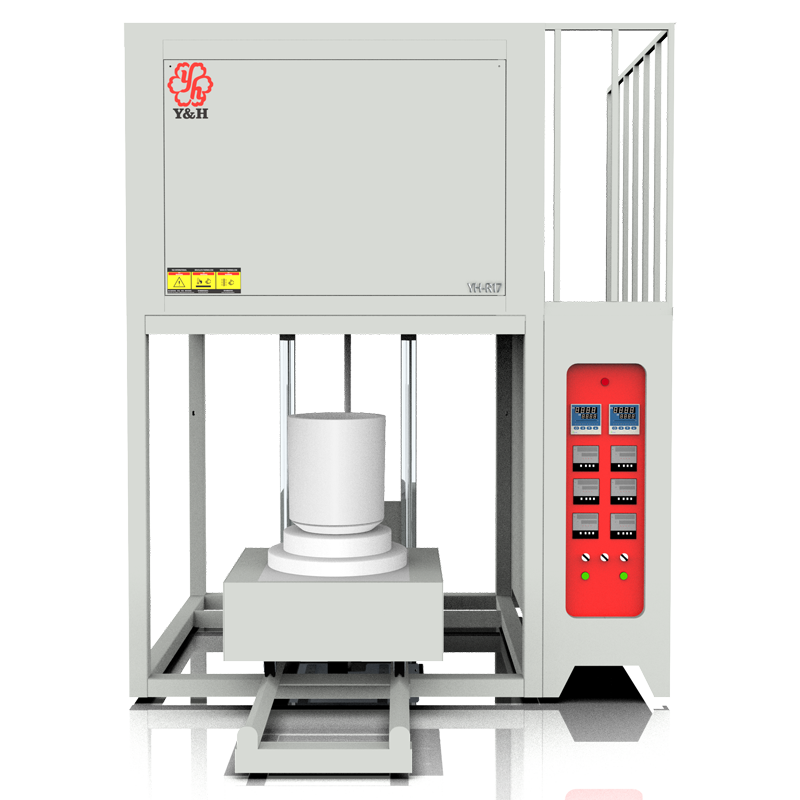

YH-R17

The integrated high temperature frit furnace is a special type of frit furnace for the manufacture of optical glass and ceramic grinding wheel bond. Such furnaces are often designed to meet the needs of the optical and grinding industry for high-quality optical components and grinding wheel bonds. Frit furnaces generally contain an open furnace, which is used to heat the crucible placed inside, so as to melt the powder or other materials inside the crucible, and the material after high temperature melting will flow out through the discharge port at the lower part of the crucible. The effluent material can be fed directly into the mold or for water quenching analysis or into the mold and roll equipment.

The design and operation of such furnaces usually take into account the following factors:

High temperature requirements: Optical glass and ceramic grinding wheel bonds usually need to be melted at high temperatures to ensure that their components can be fully mixed and achieve the desired physical properties. The general temperature is above 1600 ° C, so silicon molybdenum rod is usually used as a heating element.

Melting process control: The melting process is controlled to ensure that the components of the optical glass and ceramic wheel bond are evenly mixed and achieve the desired chemical composition. After the target temperature is reached, the molten material flows out through an outlet in the lower part of the crucible, and the flow time can be artificially controlled by an appliance using a stopper.

Crucible selection: The use of high temperature resistance and chemical stability of the material to build the crucible, generally the use of high purity quartz crucible as the carrier, no extreme cold and hot conditions of high purity quartz crucible stable properties, and more economical. Quartz crucible can be used in the same batch for a long time, but can not be reused in different batches (there is an extremely hot and cold situation when closing the electric furnace, which will cause the crucible to crack), if you need to use for a long time and the need not to crack, you can choose platinum crucible. To ensure long-term stable operation under high temperature conditions.

- Temperature control: The temperature during the melting process is precisely controlled through the use of only thermometers and thermocouples to ensure that the produced optical glass and ceramic wheel bonds meet the required quality standards.

Optional Features:

Control mode customization: PID control by the traditional domestic instrument, can be customized imported instrument or PLC control. A variety of options to meet different customer habits.

Platform access and quantity: Platform access can be customized for automatic walking, and the number of platforms is up to 2, which can meet the requirements of loading (unloading) materials while firing.

Touch screen control: Y&H can make touch screen control system according to the popular industrial touch screen collection on the market, reports, data, real-time observation and download.

Mixing system: If the material needs to be stirred in the process of firing, the mixing function can be customized, and the mixing speed can be controlled by frequency conversion.

Standard specification

Product | Temp | Crucible Size | Voltage | Power | OD(mm) | Weight(kg) |

YH-R17 | 1200-1700 | 10L | 380 | 20 | 1100*1100*1450 | 300 |

17L | 40 | 1100*1100*1700 | 450 | |||

Remark: |

| |||||