An optical glass/ceramic bonding agent frit furnace is a special type of frit furnace used for manufacturing optical glass and ceramic bonding agents. This furnace is typically designed to meet the needs of the optical and grinding industries for high-quality optical components and bonding agents.

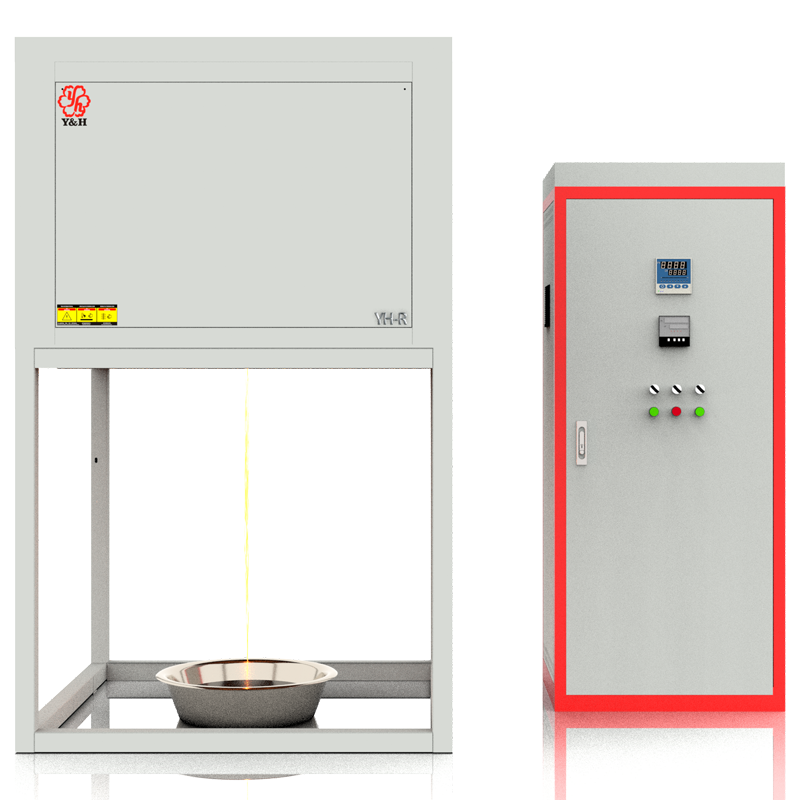

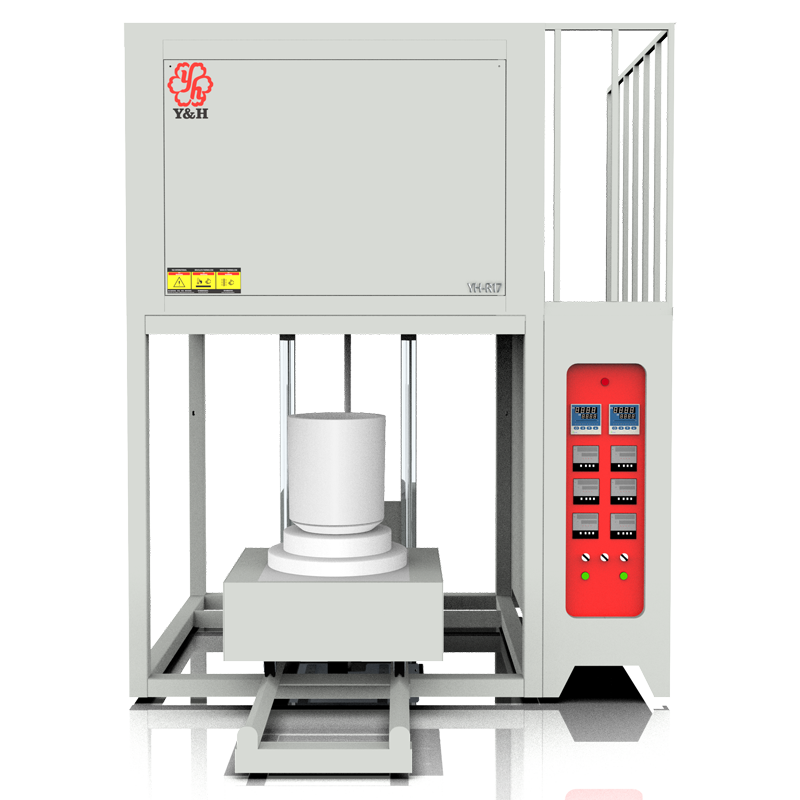

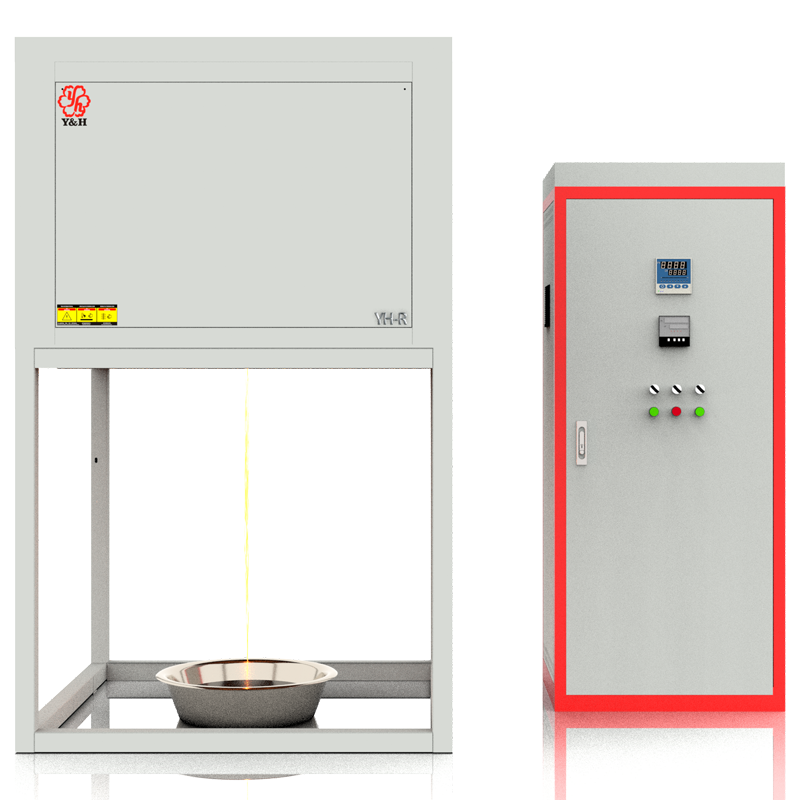

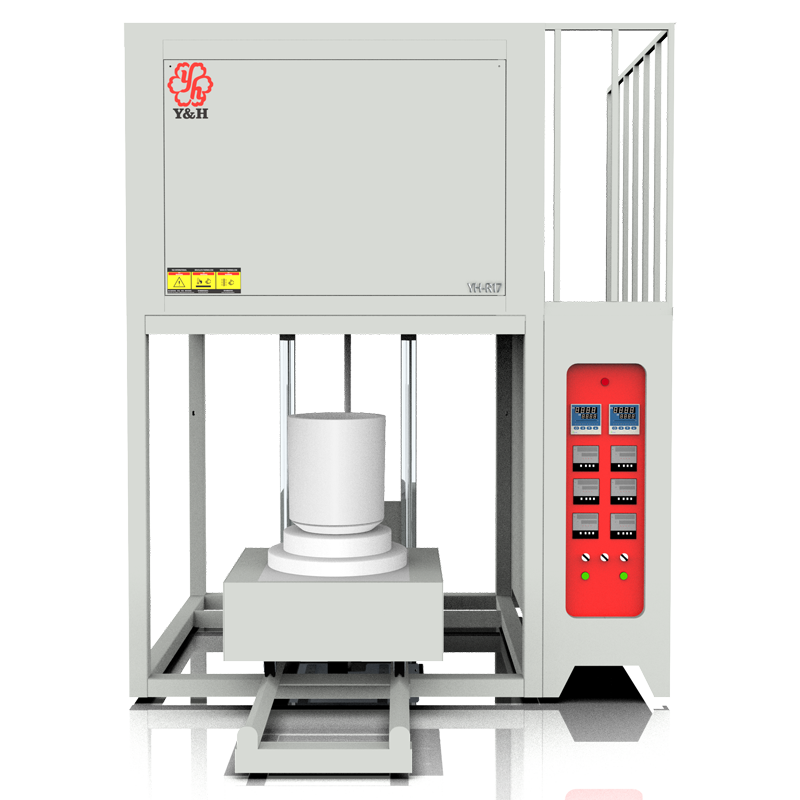

A frit furnace heats materials by placing them inside a specially manufactured high-purity fused quartz crucible. External resistance heating elements heat the crucible, transferring temperature to the materials inside and melting them into a molten or liquid state for subsequent industrial processing. This process is often complemented by rolling mills or quenching equipment.

The Frit(melting) furnace is typically used in industries such as the production of ceramic grinding wheel binders, testing optical glass compositions, and preparing frits, low-temperature glass melts, enamel for ceramics, and binders in laboratories for ceramic, glass, and enamel industries. Additionally, it can serve as production equipment for small-scale enterprises.

The frit furnace typically used for melting glass powder or ceramic powder, is referred to as a melting furnace. They are used in resistor furnace manufacturers for formulation experiments or industrial production, primarily to heat solid powder materials to a sufficiently high temperature to melt them into a liquid state for subsequent processing or shaping. Melting furnaces are typically designed with a specially made high-purity quartz crucible to contain and heat the materials, ensuring uniform and stable melting at high temperatures.