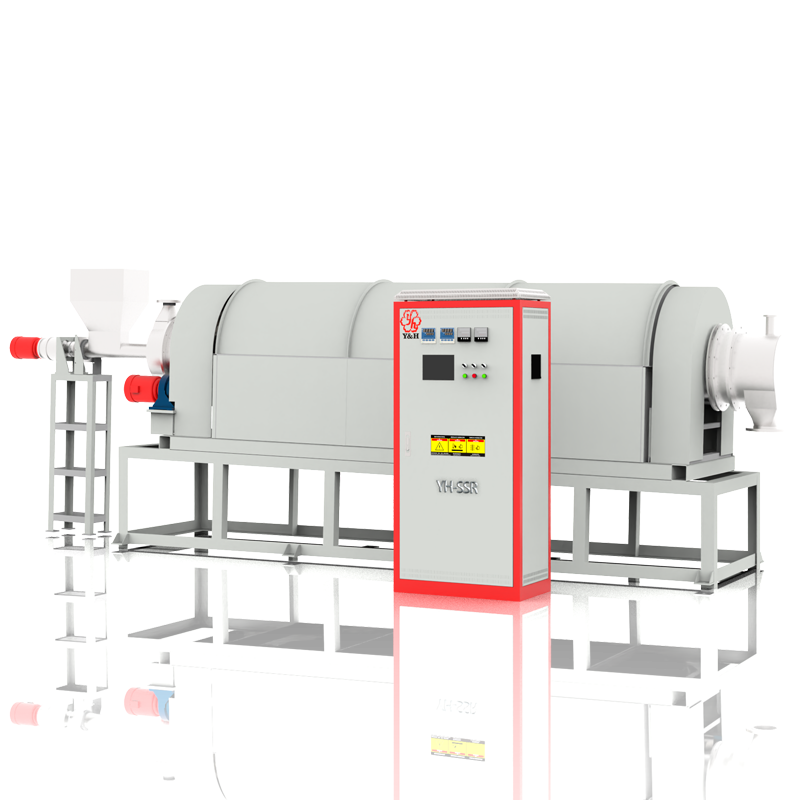

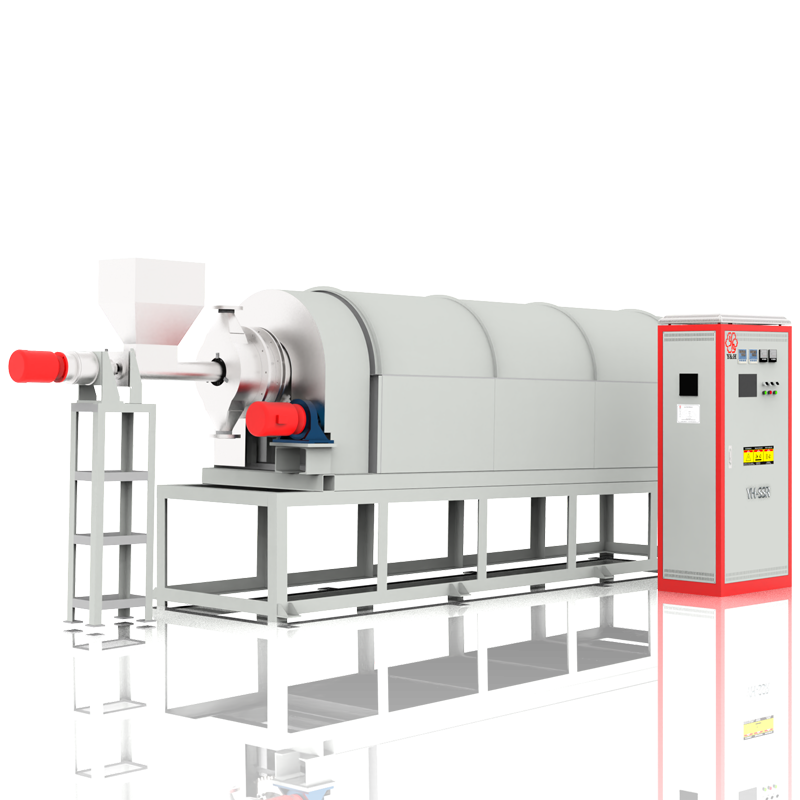

YH-SSR

A high-temperature resistance heating rotary kiln is an industrial equipment designed specifically for high-temperature sintering processes. It utilizes resistance heating elements such as resistance wires, silicon carbide rods, or molybdenum disilicide rods to convert electrical energy into heat energy for heating and processing various materials. This kiln typically consists of a feeder, a furnace body, and optionally a cooling section, used to transport materials into the inner tube of the furnace. The outer surface of the furnace tube is covered with high-temperature refractory materials and heating elements, where heat is transferred from the heating elements to the furnace tube. The furnace tube then transfers heat to the materials being processed, while its tiltable rotation ensures uniform heating of the materials at high temperatures.

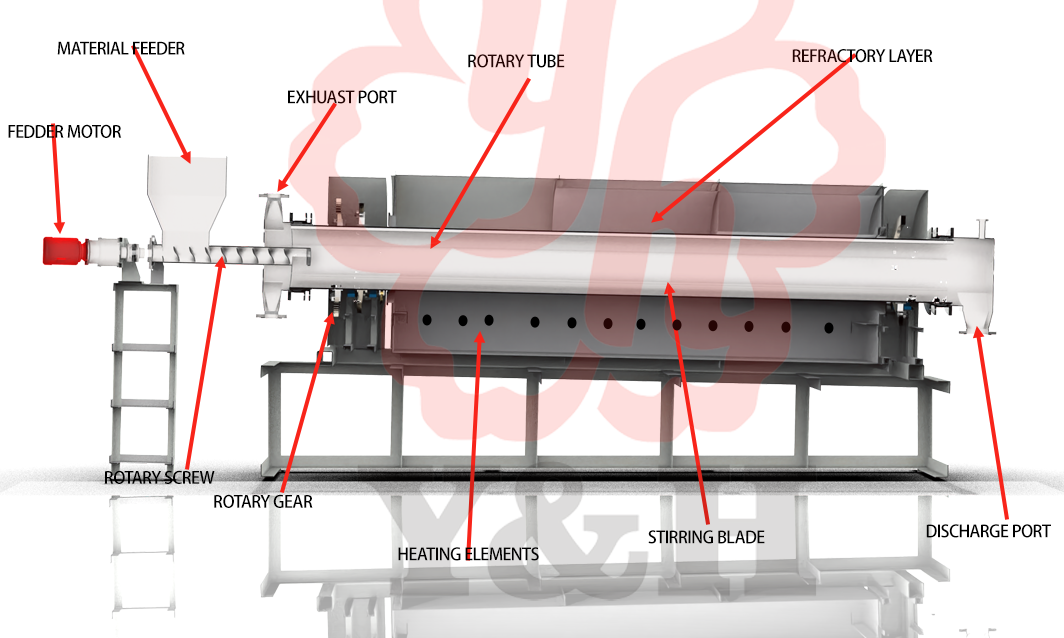

Rotary Kiln Working Principles

(schematic diagram)

Conveying materials of different properties through screw feeder (variable frequency control) into rotary kiln's tube, The rotary kiln itself will be installed with a certain tilt Angle(Maximum 5 Degree),As the tube rotates, the material will automatically fall into the tube and pile up at the end. Customers can make corresponding Settings according to their own heating process. The furnace will heat up by itself according to the parameters set. After heating up, the discharging operation can be carried out. If the discharge temperature is too high, the tail can be considered to add cooling section (water spray, or other cooling methods can be customized).

Standard features

- 1700°C maximum operating temperature(Depends on the furnace tube material)

- Kiln tube diameter( Metal tube maximum 1200MM, The quartz tube&alumina tube maximum 200mm)

- Kiln tube Length(Can be customized base on customer's production process)

- Double layer furnace shell air cooling ensure the surface temperature less than 45℃

- Vacuum forming ceramic fiber board, light weight, good heat preservation and energy saving effect.

- Silicon carbide rod or silicon molybdenum rod fitted as standard

- Double layer protection(over current, over temperature and over voltage etc

- Incline degree(0-5° can be customized, Fixed during installation and debugging)

- With stepless speed change, the speed of rotation can be controlled

- Heating zone length and quantity can be customized

Options (specify these at time of order)

- Control software and system.

- Multi-face heating

- Anti-corrosion

- Multi-temperature control

- Vacuum requirements

- Tube Materials(Stainless Steel,Quartz or silicon carbide or corundum)

- Feeder Volume

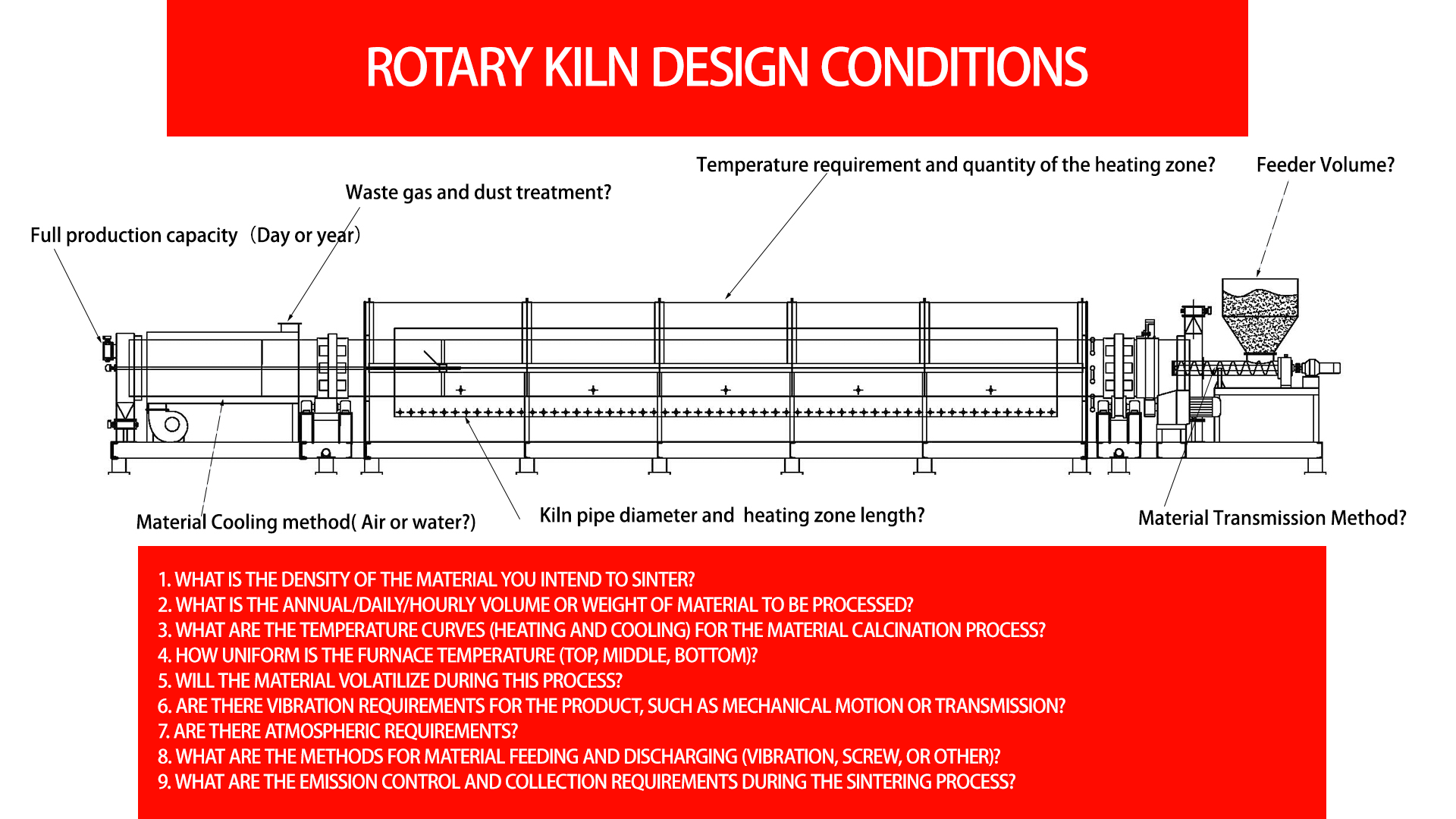

Design conditions(Customers need to give answers, design needs to refer to the following answers)

- What is the density of the material you want to sinter?

- Volume or weight of materials to be handled per year/day/hour

- Material calcination temperature curve (temperature rise and cooling curve)?

- Furnace surface temperature uniformity (top, middle, bottom)?

- Will the material evaporate during this process?

- Is the vibration requirement of the product mechanical movement or transmission?

- Is there an atmosphere requirement?

- Material feeding and discharging method (vibration, spiral, other)?

- Soot emission and collection requirements in the sintering process?