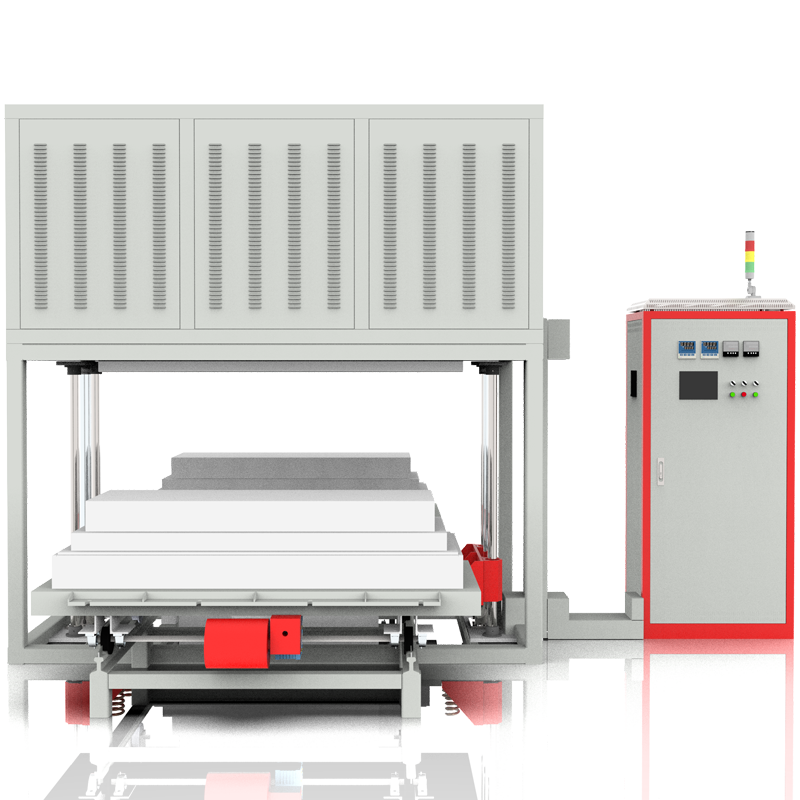

Bottom loading furnace is an industrial equipment used for high-temperature treatment processes, commonly applied in fields such as metallurgy, glass manufacturing, and ceramic production. Its primary feature is the ability to adjust the height of the furnace bottom through lifting devices, thereby controlling the contact time and temperature of materials within the furnace chamber. Typically operating within a temperature range of 400-1700°C, this equipment's basic structure comprises the furnace body, heating apparatus, and bottom lifting mechanism. Heating is achieved through resistance heating, with specific material selection depending on process requirements and material properties. The design of the bottom lifting furnace enhances process flexibility and efficiency by allowing adjustments to the furnace volume and material processing time as needed.

When choosing a bottom lift furnace, you must take into account the type of material to be treated, capacity requirements, energy costs and environmental requirements. Detailed process design and cost-benefit analysis are often required to determine the most appropriate equipment type and specifications. Generally speaking, the lifting furnace can be divided into hydraulic lifting kiln and screw lifting kiln according to its lifting method. Customers can choose according to their own situation.

The bottom loading high temperature furnace is suitable for many fields, including universities, scientific research institutes, industrial and mining enterprises. It can be used in powder processing, electronic device manufacturing, metallurgical experiments, medical heat treatment, ceramic production, sulfur melting, glass new material preparation, chemical reaction and metal sintering and other high temperature heating treatment applications.

Bottom loading furnace is a kind of large sintering or heating equipment. It is usually composed of one or more heavy load-bearing platforms, the platform is moved and lifted into the furnace chamber, and the required material or workpiece is heated so that it reaches the temperature required for the reaction.