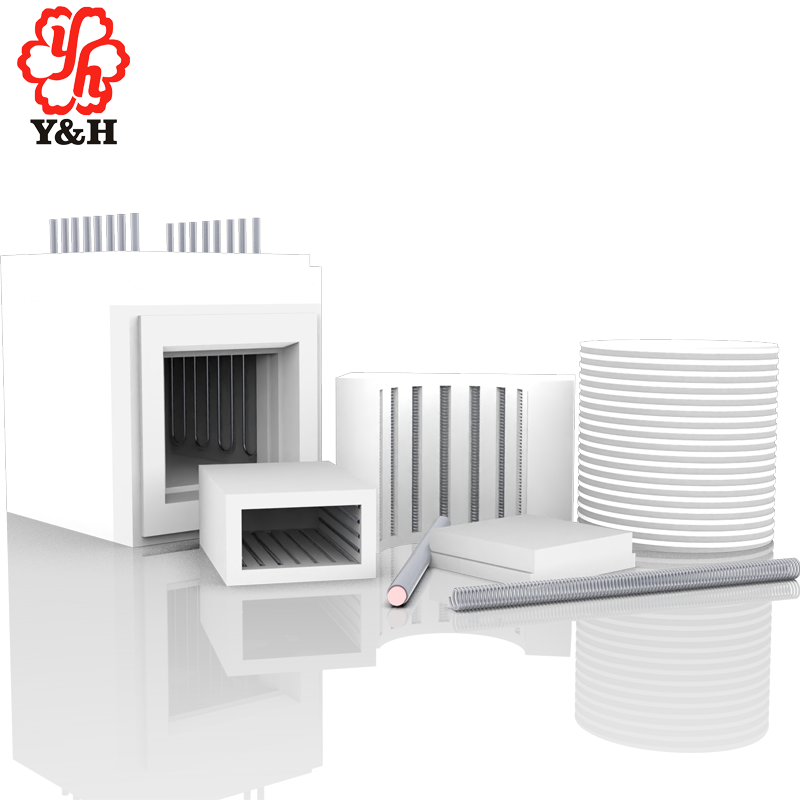

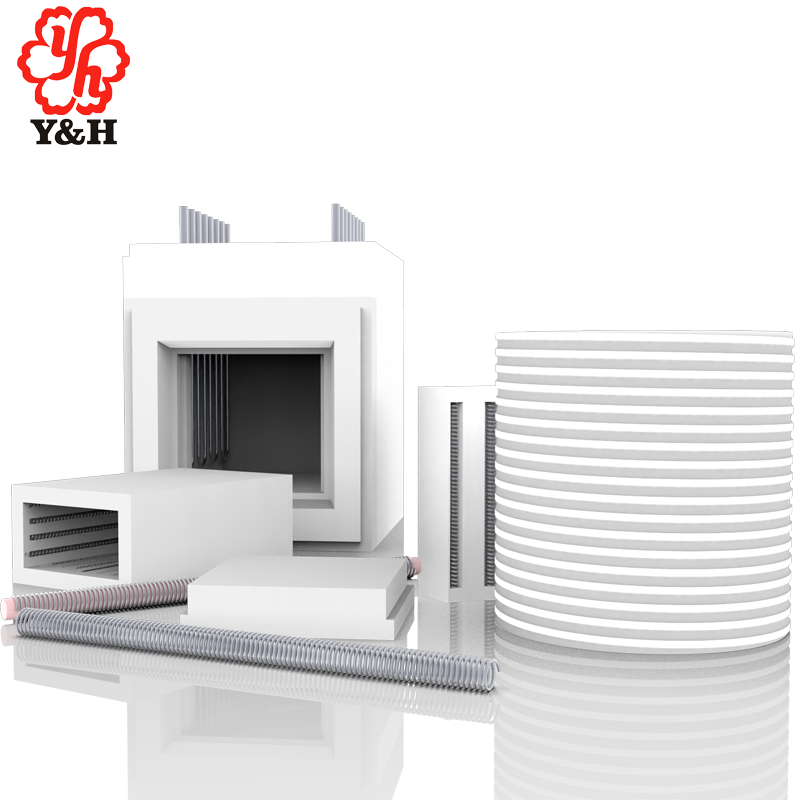

Ceramic Fiber Furnace Chamber

"Ceramic fiber furnace chambver" typically refers to a furnace using ceramic fiber as insulation material. Ceramic fiber, known for its high-temperature resistance and low thermal conductivity, is suitable for manufacturing various industrial furnaces such as heat treatment furnaces, melting furnaces, and crucibles. Its use helps to effectively reduce heat energy loss and improve energy efficiency.

Advantages of ceramic fiber furnaces include lightweight, high temperature resistance, low thermal conductivity, and good chemical stability, making them suitable for various industrial applications. Additionally, the flexibility and softness of ceramic fiber allow for the manufacturing of furnaces in various shapes to meet different process requirements.

Ceramic fiber furnace chambers exhibit the following characteristics:

Excellent thermal insulation: Ceramic fibers have low thermal conductivity and high thermal insulation properties, effectively reducing heat transfer and loss, thereby enhancing furnace energy efficiency.

Lightweight: Compared to traditional refractory materials, ceramic fibers are lighter, facilitating easier installation and maintenance, reducing structural burden on equipment, and contributing to energy savings.

High temperature resistance: Superior resistance to high temperatures allows ceramic fiber furnaces to operate stably in high-temperature environments for extended periods without deformation or damage.

Chemical stability: Ceramic fibers demonstrate good stability against many chemicals, resisting corrosion and oxidation, thus prolonging furnace lifespan.

Low heat capacity: The low heat capacity of furnace materials enables faster response to temperature changes during heating and cooling processes, aiding in process control and improving energy efficiency.

Excellent acoustic performance: Ceramic fibers possess good sound absorption characteristics, helping to reduce noise generated during furnace operation.

Overall, ceramic fiber furnaces are widely utilized in industrial production due to their outstanding thermal insulation, lightweight nature, high temperature resistance, and chemical stability. However, due to material characteristics, minor cracking may occur during high-temperature use. While small fissures do not affect furnace performance, if cracks enlarge over time, repairs or replacements may be required after a certain period of use.

Specific material performance parameters can be referenced for ceramic fiber boards.