High-purity alumina products

High-alumina crucibles or saggers are refractory containers made from materials with high alumina content (typically referring to materials with more than 50% alumina), used in calcination or sintering processes. They come in various structures such as supporting plates, saggers, pillars, molds, pusher plates, lids, and bowls, tailored to different process temperature requirements based on varying alumina oxide content. They are suitable for sintering magnetic materials, PM stainless steel, ITO targets, and other applications, allowing customers to choose different structures and material compositions according to their specific process needs.

Key Features and Benefits:

High-temperature resistance, excellent impact resistance, low thermal expansion coefficient, and high resistance to creep deformation.

Low heat absorption, beneficial during MIM stainless steel sintering to prevent issues like carburization, decarburization, and chromium depletion caused by chemical reactions.

High surface finish and precision V-grooves ensure the ceramic product's sintering cleanliness and dimensional accuracy.

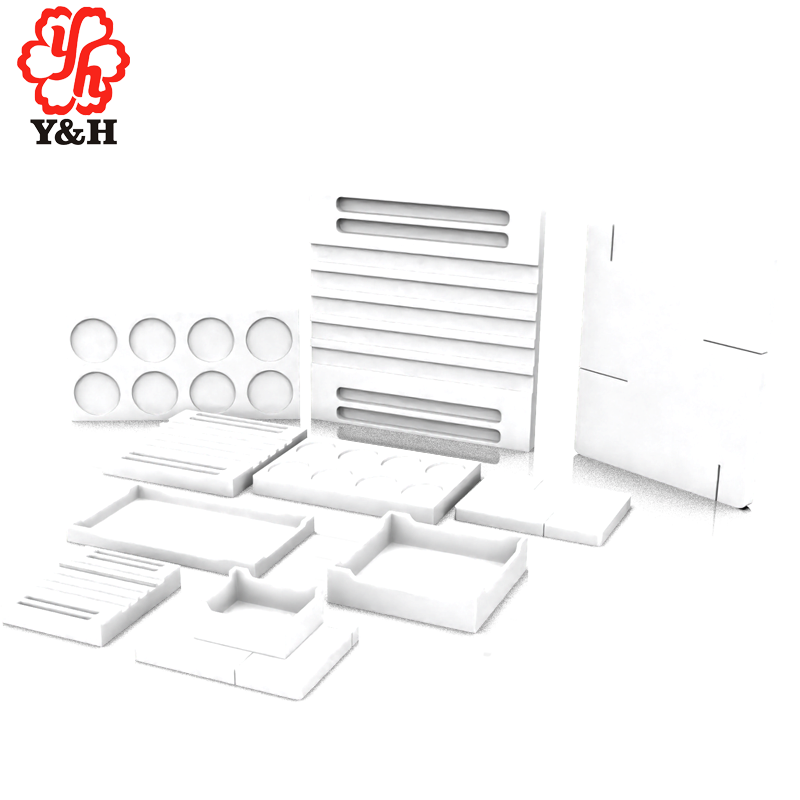

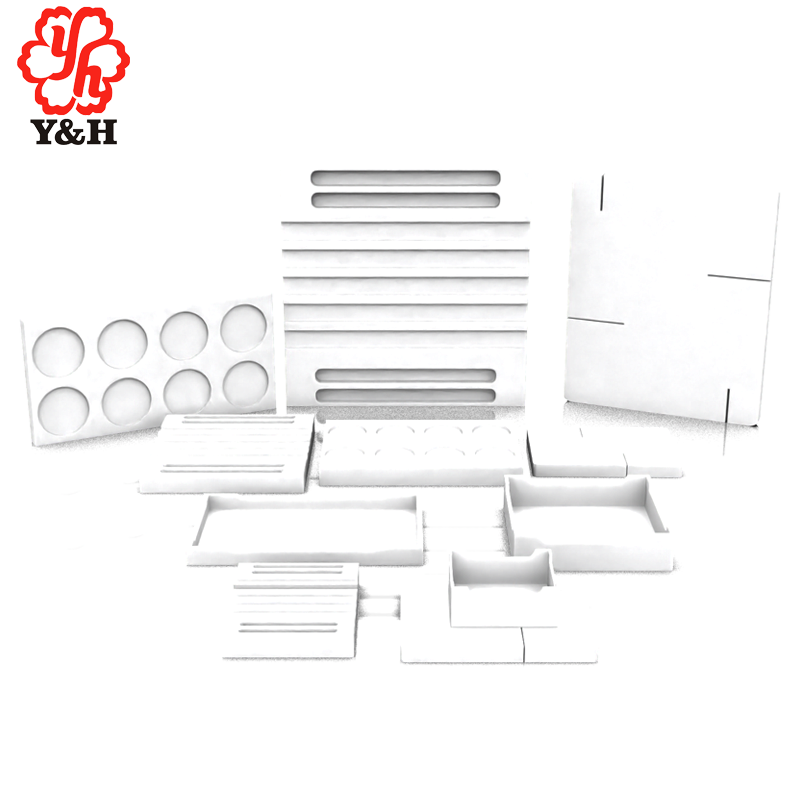

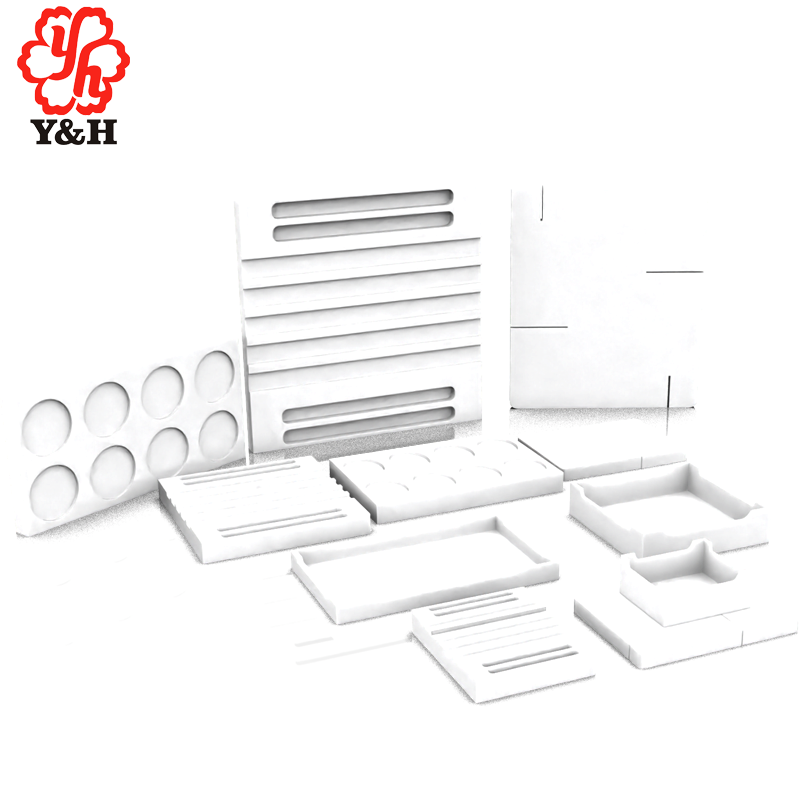

Product component

Project | HR88 | HR90 | HR91 | RB95 | Big Plate |

Al2O3(%) | 88 | 90 | 90.5 | 96 | 88.5 |

SiO2(%) | 11.5 | 9.5 | 9.2 | 3.8 | 11.2 |

Fe2O3(%) | 0.08 | 0.06 | 0.08+NaO(≤0.016) | 0.06+NaO(0.1) | 0.08 |

Using Temperature °C | 1650 | 1650 | 1650 | 1650 | 1650 |

At 1000°C Thermal Expansion rate *10-6 | 5.6 | 6.0 | 6.0 | - | 5.5 |

At 1400°C Flexural strength(Mpa) | 13.5 | 16.5 | 16.5 | - | 16 |

Apparent porosity | 15 | 14 | 15 | 14 | 14 |

Density | 2.98 | 3.0 | 2.98 | 3.0 | 2.95 |

Y&H offers customization according to customer requirements to meet their needs in sintering fine ceramics of alumina/zirconia, injection molding of stainless steel powder metallurgy, as well as low-temperature co-firing ceramics, magnetic materials, and cathode materials, among others. We provide a variety of structures such as supporting plates, saggers, pillars, molds, etc., with customizable options for sizes and shapes.