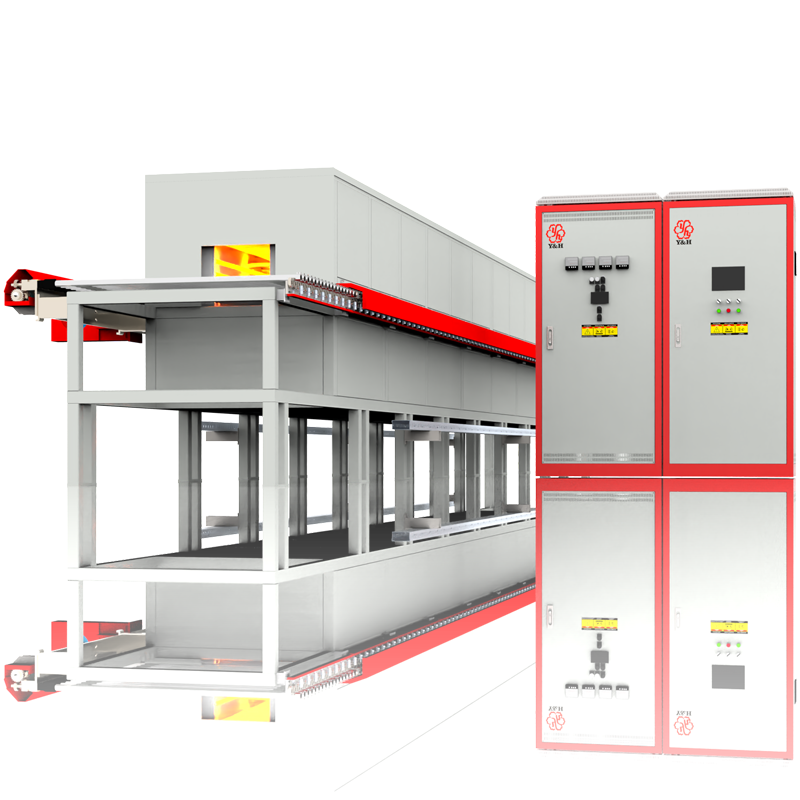

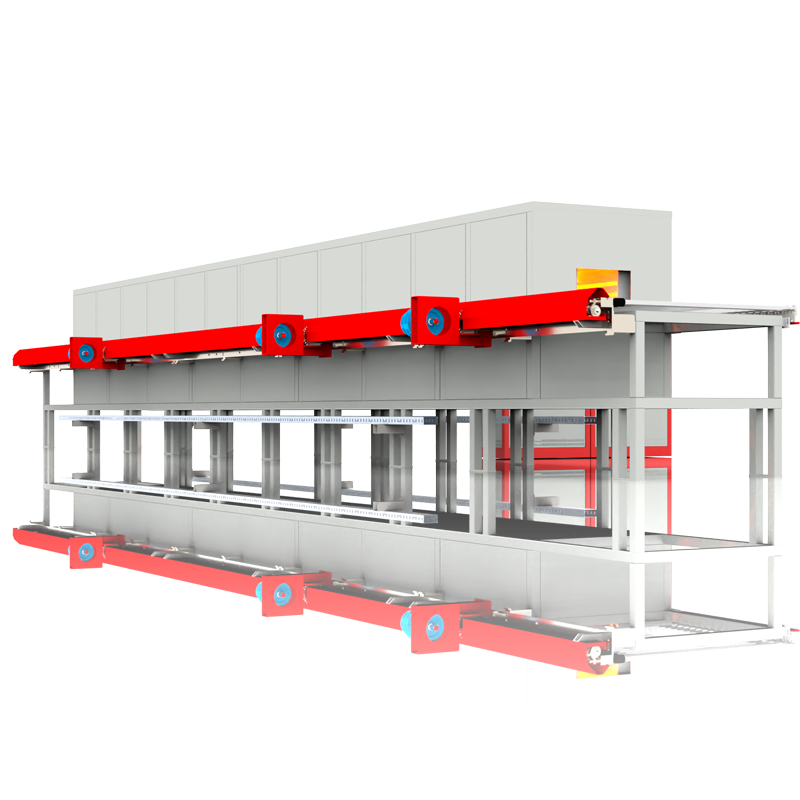

YH-CRK

A roller kiln is an essential equipment used for sintering, drying, and production of new materials or battery raw materials. It is a continuous kiln typically composed of multiple heating zones connected by rollers. In a roller kiln, materials are usually placed in boxes or trays, which travel along horizontal rollers entering from one end of the kiln, passing through various heating zones within the kiln, and exiting from the other end. During this process, the materials inside the boxes or trays are continuously heated to complete the sintering or firing process. Temperature and time are controlled according to a set heating profile to ensure the products achieve the desired quality and physical properties.

A roller kiln is a tunnel kiln with narrow and long sections. Different from kiln car tunnel kiln, it is not operated by kiln car loading products, so the structure of the kiln roof is a flat ceiling. The "roller table" is composed of rollers arranged in parallel across the working channel section of the kiln. Products are placed on the roller table and transported into the kiln with the rotation of the roller. The firing process is completed in the kiln.

The main features are as follows:

the highest working temperature up to 1400℃ (according to the requirements of different products)

Good insulation effect

high-quality kiln wall and roof insulation system, greatly reducing heat scattering

the use of high-quality resistance wire or silicon carbon rod heating components

hot area according to the needs of distribution, to ensure that the production efficiency is fast, high efficiency

Advanced control and the setting system ensure constant pressure in the kiln and high-temperature control precision